The Blue View - Local Experts

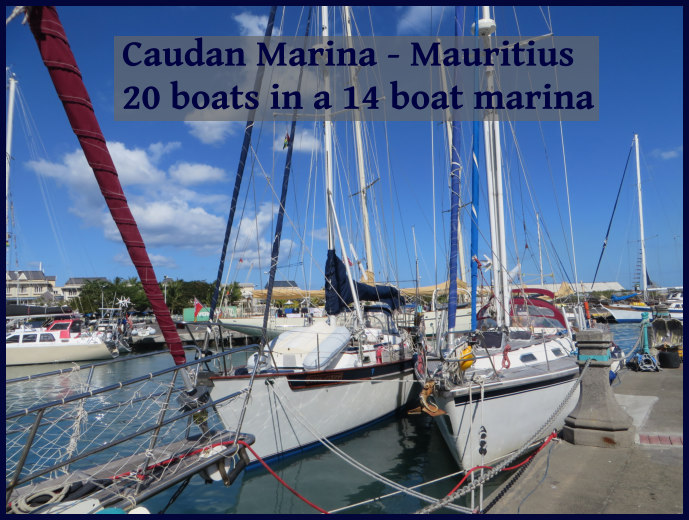

/As I write this, we are rafted up against a boat, who is in turn tied up to a concrete jetty in Mauritius. Mauritius is a stopping place for most of the boats making their way from either Australia or Asia to South Africa, and because of the weather cycles and the cyclone season in the South Indian Ocean, almost all of them arrive here between mid-September and mid-November. This year is no exception, and the tiny marina is pretty full, with boats rafted up two deep all along the jetty.

Since all the boats have arrived here after a long passage from somewhere, most have problems to be resolved and things to be fixed. My list is fairly short, the biggest thing being the bent toggle on the end of our whisker pole that I would like to get replaced. We will need a machinist with a milling machine and lathe, and who has access to 1” (25mm) round stainless steel rod. The boat next to us has engine problems and issues with both their satellite and HF radio communications; the boat across from us needs repairs to their generator; another nearby boat has a bad engine heat exchanger and a leaking water heater...

It isn't surprising that a cottage industry has developed here with lots of 'experts' to help us sailors make our repairs. There are mechanics, electrical and electronic techs, sailmakers, machinists and carpenters, all intent on making enough money from the cruisers during this three month period to tide them over for the rest of the year. Since we are perceived as wealthy and naïve (stupid maybe?), and since we will only be here a week or two before moving on, probably never to return, we are ripe for the picking. I am sure some of the specialists actually have some expertise in their fields, and are honest and reliable tradesmen. I am equally sure there are just as many or more of these 'experts' who know a whole lot more about how to take advantage of cruisers than they do their purported field of expertise. The problem, of course, is determining one from the other without getting burned too badly.

The boat with the generator problem has been here almost a month and has spent over $3000 to date, as one after another part was determined to be the cause of the problem. Each part was air freighted in and installed, but when the problem persisted, the mechanic explained there was yet another bad part. Three expensive parts have now been replaced, and the mechanic is no longer returning the skipper's calls.

The boat with the communications problem had a slightly better experience – the technician replaced only two parts, the tuner and the modem, but at least his HF radio now seems to work. The mechanic that worked on the heat exchanger dismantled it and welded the damaged section, promising to have it back and installed in the next day or so. If it works and the price is not exorbitant, I'll happily conclude there is at least one honest and knowledgeable tradesman here.

Our past experiences with local experts have been somewhat better. In most places, we have been able to find wonderful people who charged a fair price. But we have also been burned enough times to make me quite wary when I began looking for a machinist to make the part for the whisker pole.

In most port towns that cater to yachties there is a guy, usually a taxi driver, that makes his living helping the cruisers – whether it be getting diesel, providing tours, finding a part or locating the right expert. Sometimes the guy is trustworthy and has built up a good reputation among the cruisers – Jesse James in Trinidad is a good example. Sometimes the guy is a total scoundrel, gouging the yachties to make a quick buck, but word soon gets out and these guys don't last long. More often, however, the guy is somewhere in between. He knows where everything is and who the good experts are, but charges a lot for this information.

Rashid is the yachtie 'go-to' guy here in Mauritius. He introduced himself to us before we even got our dock lines tied up. We had heard of Rashid from other cruisers, and he had mixed reviews. Some felt he was fair, but expensive, while others felt he had gouged them. Thus, I was a bit wary when I asked Rashid if he knew a machinist who could make our our whisker pole toggle.

To remove the old toggle would require several hours of work. A corroded set screw would have to be drilled out, and it would take a lot of persuasion to get the toggle free. I didn't want to go to all this effort until I was sure I could get the replacement part made and at a reasonable price.

I asked Rashid if he knew a machinist that could make the toggle. After a quick look at the whisker pole, he replied “Oh yes, my friend, I know a man who can make just such a thing. Give me the part and I will get you the new one made.” Hmmm. I said “I need to talk to the machinist first, to make sure he has the right material and to find out how much it will cost.” Rashid replied “ Trust me, my friend, this man has all types of stainless, and the price will be very cheap.” I really didn't want to remove the old toggle and hand it over to Rashid based on this. I said “I have a drawing and some photos of the old part. I really need to talk to the machinist.” Rashid replied, somewhat reluctantly I thought, that he would take me to the machinist. I asked Rashid what the cost was for the taxi ride, and he replied “Don't worry – it will be a good price and we can work it out later”.

I hopped in his taxi, and we took a 10 minute ride through a maze of back streets, arriving at a small machine shop inside a garage. I showed my drawing and photos to the machinist, who assured me he could make the part and had access to 316 stainless. I asked him the cost, and he replied “Don't worry, my friend, it will be very cheap”. We returned to the marina, whereupon Rashid told me the taxi fare was 500 Rupees – about $18. I said that this was about triple the usual taxi fare. Rashid replied with a shrug, “Maybe, but a regular taxi wouldn't know where the machinist was.” Good point.

I paid the 500 Rupees – but I've decided the toggle can wait until South Africa. Once I hand over my old toggle and the machinist makes a new one, I will be obligated to pay whatever he asks. Despite his assurances, my “very cheap”, blue-eyed special price may well end up being considerably more than I think it is worth.