The Blue View - Finding the Current

/There are a number of ocean currents around the world, and we've experienced several of them first hand on Nine of Cups. There is the Humbolt Current, a north setting current on the west coast of South America that we fought most of the way down the coast of Peru and Chile. There is the south setting East Australia Current that gave us (and little Nemo in the Disney classic) a fast ride from Bundaberg to Sydney. The Benguela Current assisted us sailing north out of Cape Town the last time we were there. We either made use of or tried to avoid the Gulf Stream Current on our several passages up and down the east coast of the USA.

In general, we greatly prefer to go with the current, if possible, but sometimes the currents are contrary to expectations. On our Indian Ocean crossing, we sailed the routes that the pilot charts indicated had favorable currents, but encountered an amazing number of adverse counter-currents, Other boats, a mere 40 or 50 miles away, had a one or two knot push from the currents they saw, while we were losing one or two knots from a current going the opposite direction. Perhaps the tot of rum they gave Neptune was more to his liking than the Bundy rum we were offering.

On our passage from Durban to Cape Town, we were looking forward to, but anxious about the Algulhas Current. This current flows along the west and south coasts of South Africa, and reaches speeds of 5+ knots. Only the Florida Current and portions of the Gulf Stream attain higher speeds. The Algulhas Current makes for very fast passages, but if you get caught in it when a “southbuster” comes through, the wind against the current can create huge, deadly waves. Many of our new friends in Durban and East London had stories of vessels lost along this coast when the winds didn't behave as predicted.

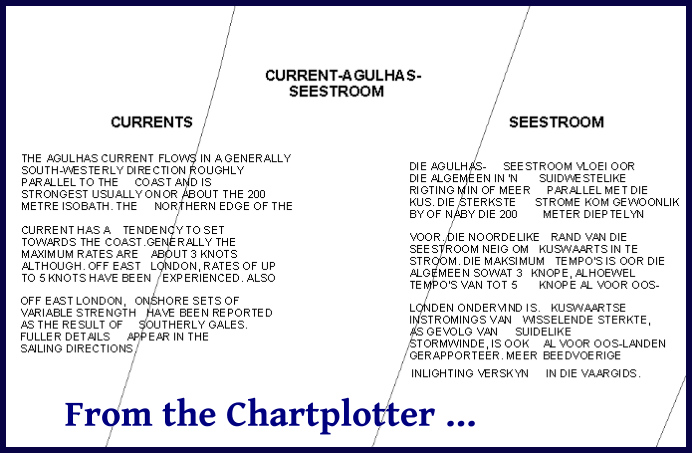

The first trick is finding the current. We had all sorts of conflicting advice. The pilots and sailing directions advise finding the 200 meter (660 feet) depth contour and maintaining that depth along the coast, as this is the edge of the continental shelf. Some local sailors said that we would have a faster passage if we followed the 30 meter (100 foot) contour, and stayed only 2-3 miles offshore. Others insisted that we should head offshore until we found three knots of current, then follow that depth contour. Maybe the contradictory advice was due to the fact that the current apparently changes location. The local cruising guide states that “Periodic meanders can move the Algulhas Current as much as 100 miles offshore. Meanders can shift the core by as much as 10 or 20miles in a day.” We decided to head for the 200 meter contour and hope the current wasn't presently off on one of its meanders – or gone on a walkabout.

This plan worked quite well for us on the Durban to East London and the East London to Port Elizabeth legs of the passage. We picked up 2.5 knots at the 200 meter contour, and as we followed it, the current increased to 3.5 knots, then 4 knots, and reached a maximum of almost 5 knots. We had two very fast passages, and while the winds were higher than predicted, they were from the right direction.

The 200 meter contour strays from the coast after Port Elizabeth, and if we were going to continue following it, we would have to sail almost 30 miles offshore. Despite the extra miles, if we found 3-4 knots of current, we would still have a faster passage to Mossel Bay than if we sailed a direct course, so we decided to head out to sea until we found the Algulhas Current once again. We sailed southeast 30 miles until we reached a depth of 200 meters - no current; 35 miles – no current; then 40 miles and still no current. Should we keep going offshore? Maybe we'd find the current in another mile or so. Or maybe it was off meandering, and we would need to sail another 40 or 50 miles to find it.

We decided to cut our losses at 40 miles and headed eastward. The extra miles and lack of current put us into Mossel Bay at midnight the next night instead of a hoped-for afternoon arrival, but the anchorage was wide open and calm. We tidied up and hit the bunk, and I had nary a dream about where that pesky current was off to.

for the size and

for the size and  for the gold leaf.

for the gold leaf.