The Blue View - A Review of the Boss

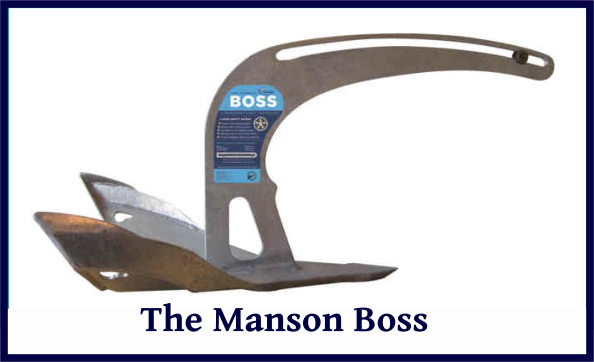

/No, this isn’t a review of Marcie... this is an update on our Manson Boss anchor. We purchased our Boss anchor a few years ago when we were cruising the south coast of Australia. Until then, we had been using a 110# (50kg) Bruce anchor, and although it had a few shortcomings, we had been reasonably happy with it. The south Australian coast is known for its hard sand bottoms with very thick, dense grass, however, and our Bruce claw was having difficulty digging in. I went in search of the perfect anchor – one that would serve us well there and also perform well in most other bottom types. I wrote a blog on the topic, and ended up choosing a Manson Boss anchor.

I was recently asked to do a talk on anchors and anchoring techniques at the SSCA Gam in Melbourne, FL in November. As I started preparing for it, I thought this would be a good opportunity to update my thoughts on our Boss, now that we’ve used it for a few years in a variety of bottoms. So, here’s my review of our Boss anchor:

- General. The Manson Boss is a scoop type anchor like a Bruce, except it has a very sharp, reinforced point, giving it the ability to dig into the bottom. It also has huge, up-turned flukes that ensure it is self-righting and which give it tremendous holding power once it digs in. It comes in a range of sizes from 5 lb. (2kg) to 400 lb. (182kg). We bought the biggest size that would fit our bow roller, the 80 lb. model, which was a size or two larger than the recommended size for Nine of Cups. We’ve used it in a variety of bottoms, from the hard, grassy bottoms of southern Australia, to soft sand, hard and soft mud, rocky bottoms and shell beds.

- Strength. The Boss is made of a high tensile steel. The only issue we had with the strength and construction was the upper part of the shank. The anchor has a slot along the shank that allows the anchor shackle to slide up the shank, making it easier to free the anchor if it becomes wedged in place in a rocky bottom. Manson includes a “shackle preventer”, essentially a nut and bolt that will prevent the shackle from sliding along the slot if the owner feels uncomfortable with the feature or won’t be anchoring in a rocky bottom. Our “shackle preventer” didn’t last long, and we bent the upper part of the shank trying to get it loose from one particularly rocky seabed. We removed the preventer, straightened the shank, and have had no further problems.

- Mud Bottoms. This anchor grabs and holds extremely well in the muddy bottoms we’ve encountered. Only once did we drag. This was in the Albemarle Sound in North Carolina a few months ago. We backed down hard on the anchor and thought we were stuck well on one windy night, but woke up a few hours later and found we had dragged a significant distance. My feeling is that we had fouled the anchor somehow when setting it, because it seems to have been an isolated incident - it is usually stuck so well we have to work it free from the bottom.,

- Hard Grassy Bottoms. This is the type bottom we bought it for, as our venerable Bruce was having difficulty holding in those thick, grassy, hard sand bottoms, and were happy with it for the most part. We had a few occasions when it took several attempts to get it to dig in, but we eventually got it to hold. On one occasion, we tried unsuccessfully for more than an hour to get it to set, and had resigned ourselves to leaving the anchorage and heaving-to for the night when it finally grabbed and held. We did drag a couple of times, but both times, the anchor reset and held after only dragging a boat length or so. In all honesty, we never slept all that well when the wind picked up in southern Australia. On the other hand, many of the Aussies we spoke to didn’t fare any better.

- Sand Bottoms. The Boss grabbed quickly and held well in other sand bottoms.

- Rocky bottoms. Our experience in rocky bottoms isn’t getting the anchor to set, but getting it free once it gets wedged in place. Except as noted above in the “Strength” paragraph, the Boss did well.

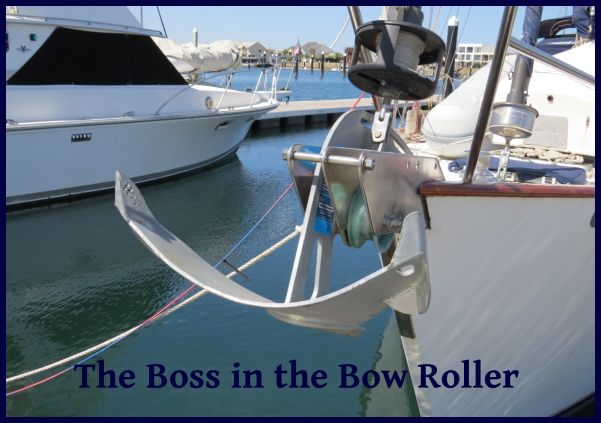

- Stowage and Deployment. The shank of the Boss is curved, making it fit well in our bow roller. It deploys well and we rarely have problems bringing it back into the bow roller (unlike our big Bruce, which had to be coaxed out of the bow roller and usually smacked the bottom of the roller furler on its way out). The only issue with stowage has to do with the large flukes. When we are in heavy seas, the waves hitting the flukes cause the anchor to bang into the bow roller and roller furler, and I had to go to great lengths to secure it well enough to prevent the anchor causing damage. In storm conditions, I would want to stow it on deck – somewhat of a hassle given its size and weight.

Overall, I would rate the Manson Boss as a B+ to A-. It set and held quite well in most of the bottoms we encountered, especially in mud and sand. In southern Australia, it was better than our Bruce, but was less than perfect. The anchor, as well as the bow roller and roller furler take a beating in heavy seas. It is a good all-around anchor and I don’t regret buying it. On the other hand, I don’t consider it the perfect anchor - if there is such a thing.

If only I had unlimited time and money, I’d make a short list of half a dozen or so anchors and try them out in the worst anchorages we’ve encountered around the world - to see whether the perfect anchor really does exist.

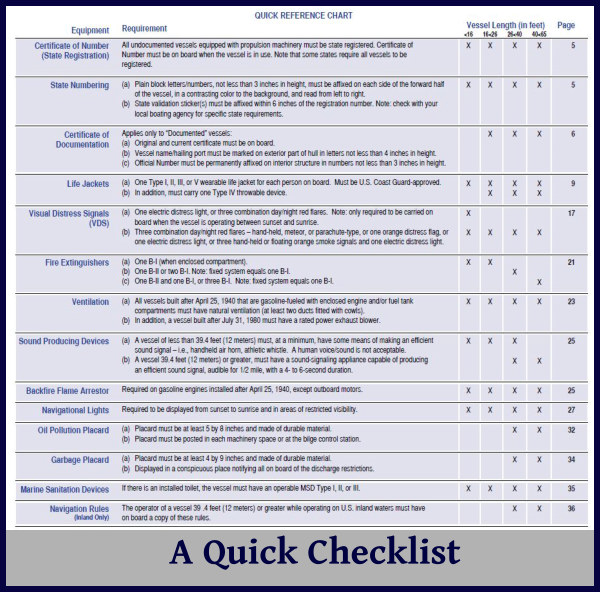

Since we were planning to spend a few days moored in Washington D.C., I thought it might be possible to schedule a U.S. Coast Guard Auxiliary inspection. According to their website, the Coast Guard Auxiliary will do a free, no-strings-attached inspection of a recreational vessel on request. If we pass the inspection, we get a signed form to that effect, as well as a decal to apply to the hull which shows that we not only requested an inspection, but that we passed. If we don’t pass, there is no fine or citation issued, nor are we reported to anyone. Any deficiencies are pointed out and the appropriate corrective measures discussed. It seemed like a no-brainer.

Since we were planning to spend a few days moored in Washington D.C., I thought it might be possible to schedule a U.S. Coast Guard Auxiliary inspection. According to their website, the Coast Guard Auxiliary will do a free, no-strings-attached inspection of a recreational vessel on request. If we pass the inspection, we get a signed form to that effect, as well as a decal to apply to the hull which shows that we not only requested an inspection, but that we passed. If we don’t pass, there is no fine or citation issued, nor are we reported to anyone. Any deficiencies are pointed out and the appropriate corrective measures discussed. It seemed like a no-brainer.