A Lofty Invitation

/Having had a new staysail made by Ullman Sails in Durban last January and thus far really liking it, we felt very confident that ordering a replacement yankee from Ullman in Cape Town was a good move. The existing yankee had caused us lots of problems over the last few years and repairing it again seemed like money down the drain. David reminded me that the old headsail was over five years old and had seen over 20,000 hard miles … southern New Zealand, the Chathams, Tasmania, the Great Australian Bight, an Indian Ocean crossing. I had hoped, of course, it would last forever, but then I still believe in the Easter Bunny.

We didn't know much about Ullman Sails. We're familiar with North Sails, the largest sailmaker in the world and then there's Quantum and Doyle and Hood Sails and Rolly Tasker Sails and a host of others. Ullman is actually the #5 sailmaker in the world, thanks to renowned American competitive sailor David Ullman. He started Ullman Sails in 1967 in Newport Beach, California and has been intimately involved in the business ever since. In 2013, Ullman combined forces with previous competitor, Jannie Reuvers Sails in South Africa. Ullman Sails is represented in 32 countries of the world, including 42 full service sail lofts. This means that if we have problems with the yankee, as we did with our previous sail, we have some recourse for service.

A good number of Ullman's sails are made right here in Cape Town. We'd become friendly with our sales rep, Winston, over the past couple of weeks and when he offered to give us a tour of the loft, we jumped at the chance.

We've visited many sail lofts over the years … usually small ones. They consist of wide open floor spaces with canvas spread out in varied stages of in-process sails. A couple of long arm, heavy-duty zig-zag sewing machines are recessed into the floor to allow easy stitching of the sails. Rolls of Dacron and colored Sunbrella UV-material are lined up along the walls. Scraps of fabric are here and there and the place is usually dusty, the hum of sewing machines and the tap of hammers providing background noise. We weren't quite prepared for the size of Ullman's facilities nor the number of people working nor the number of sails in process. It doesn't look like much from the outside as we pulled up over the curb and squeezed ourselves into a tiny parking space. Looks can be deceiving.

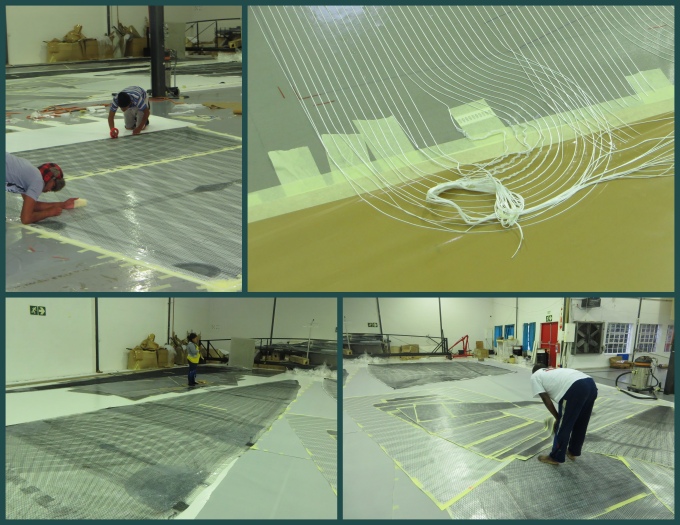

Ullman Sails' facility is huge and spread out over a city block in several buildings. We visited four multi-storied buildings and each area was a beehive of activity. After a digital design is set, the measurements are entered into a laser-cutter which works constantly, precision-cutting and numbering panel pieces for each sail.

The cut pieces are removed in order and moved to an assembly area where they are spread out on the floor, taped and ready to be sewn. UV is added later, then hardware in a different area and finally quality control is performed. I've oversimplified the process significantly, but that's the gist of it. A smooth, efficient work flow producing thousands of sails each year.

We were intrigued with their FiberPath sail construction: thousands of carbon fibers woven into a sail shape and then bonded and double-laminated. There's minimal sewing involved. There is little stretch and the primary and secondary loads on the sail are dispersed more effectively. These sails are known for speed and performance … not traits for which Nine of Cups has ever been known. The cost? Though we felt we were getting a good price for our sail, it was still quite painful to the budget. Our yankee in a FiberPath material would have effectively been a little over double the price. We'll stick with Dacron this time around.

Winston has assured us the sail will be completed in the specified timeframe. As much as we like Cape Town, we're looking forward to the day when we can sail away … with our new sail.