From Electrical Neophite to DC Darling

/Learning to do things for yourself and becoming self-reliant is one of the main criteria for becoming a successful cruiser. Here's an example in a guest post from Fiona McGlynn aboard MonArk ...

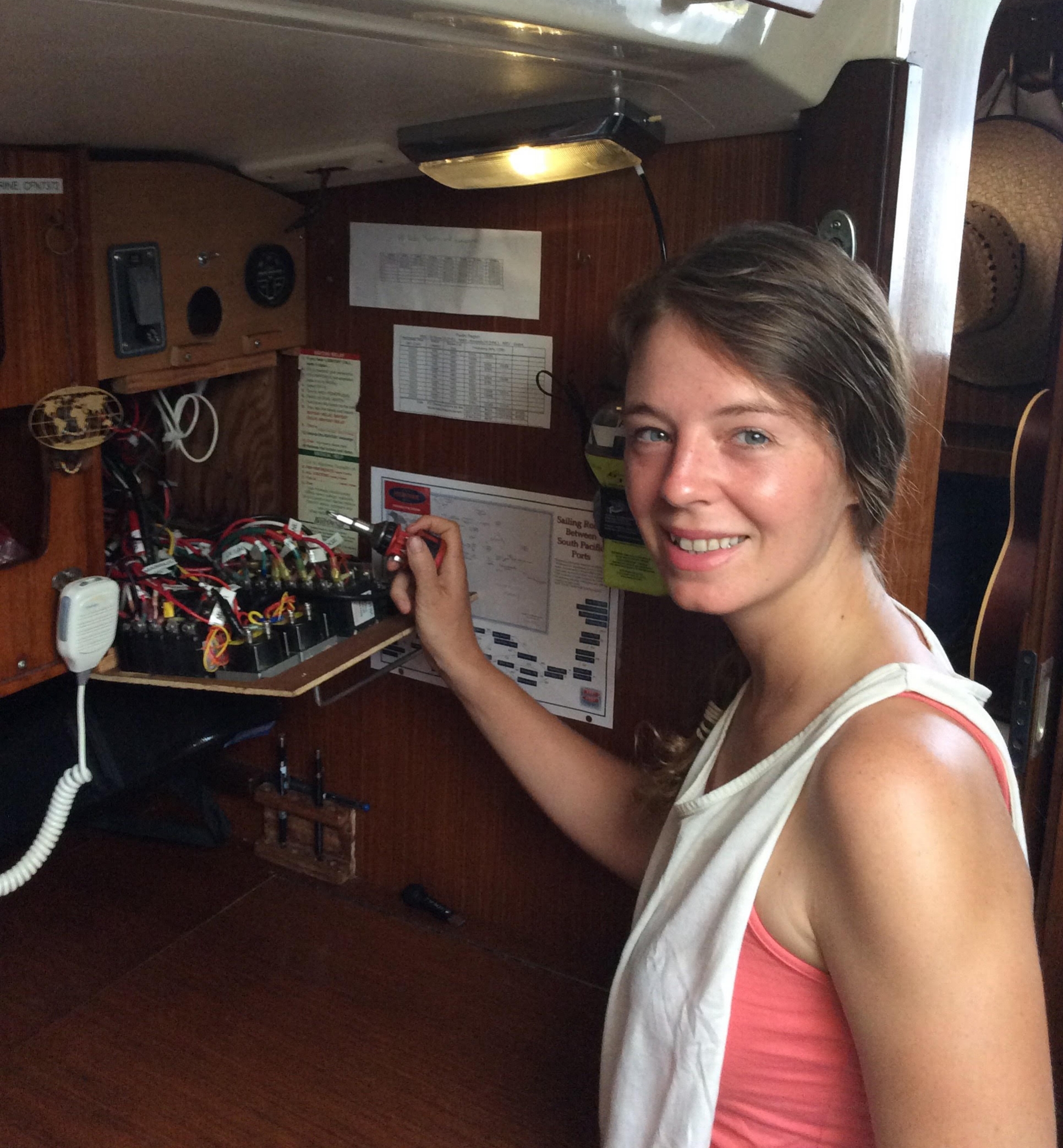

DC Darling, Fiona McGlynn shows off her electrical handiwork aboard MonArk.

Teaching Myself Basic Boat Electrical

by Fiona McGlynn

Warming up to a spring morning, Robin and I sipped coffees aboard our 35 ft sloop, MonArk. We were docked at Spruce Harbour Marina in Vancouver and busily planning for an upcoming sail to Mexico. Robin still had a month of work at his office job before we would haul the boat out of the water. Warming our hands around our coffee mugs we stared at what, at the time, seemed to be an insurmountable list: install new rigging, measure up sails, recore deck, add solar arch, replace hatches, rewire electrical… “What if I got a head start this month and replaced the electrical,” I suggested, “We could hire someone to work on it and teach me along the way.” That’s not a bad idea,” agreed Robin, “It sure would be great to replace our inverter, DC panel, and clean up the wiring.”

With just a bit of searching online I soon found our man. Fred (not his real name) was a 70+ year-old cruiser, who, when not cruising did marine electrical work. “Great,” I thought, “Who better to teach me than another cruiser!” Both Robin and I had little to no electrical experience at that point. I recall we once spent an entire morning trying to fix a light fixture that was on the fritz, bent over the instruction manual for the multi-meter. So this would be a great opportunity to build our shared skill set.

With Robin at work, Fred arrived a little after 9am the next morning sneezing and blowing his nose from what appeared to be a bad cold. We began looking through the boat’s systems, pulling back panels and face covers until the guts of MonArk were all exposed. Colourful tangles of wire spewed out of chases and cupboards. It was a right mess. Our only guides were a handful of chewed up tape labels, on which cryptic washed out markings supposedly told us what connected to what.

Fred flipped down the AC panel and peered over it, nose dripping into the morass of wires. “Are you sure you wouldn’t be better off at home getting some rest?” I asked. Nope, he assured me, he was fine. Attempting to get a better look he unpacked his trouble light and drew it right up close to the back of the panel. “Crack, pop, fizz!” went the panel, a shower of sparks shot up 3 feet into the air as the metal from the trouble light bridged the positive and negative poles. “What was that,” I exclaimed! Fred went to check the AC voltage. Nothing, there was no power coming into the boat.

It took us another four hours to sort out what had happened, and in the end it wasn’t Fred who sorted in out, but a passerby on the dock. The trouble light’s wire frame had caused a short that had blown power to not only our boat but the entire dock of 40 liveaboards! On top of that, our inverter was fried.

Fred went home to nurse his cold and I spent the rest of that rainy afternoon shopping online for battery charger inverters. What a mess! I decided that perhaps it would be easier to try and teach myself, rather than risk another mishap.

While waiting for our new 1000W Kisae inverter to arrive, I spent that week on the phone with Kisae technicians, watching helpful YouTube videos and reading blogs. I sat in our boat muttering rules and equations to myself, “Watts = Volts x Amps”, “Electricity runs like water”, “You must always have a ground”, “Red is hot, black is cold”. I pored over tables that related amperage and cable run to the correct wire size. Then one day I decided to give it a go. After disconnecting from dock power and batteries (just to be safe), I began removing rusted terminals, frayed wires, fuses, and eventually the hulking Heart Interface inverter/battery charger. Crouched in a sea of hand-drawn diagrams, steps, and notes, I carefully wired in the new Kisae inverter. As I held heat to the last bit of shrink-wrap, I began to feel quite proud, though I didn’t dare turn it on. I asked my good neighbour, Bruce, to come by and inspect my work. I sat nervously as he ran through the various connections I had made. After a few minutes of silence he said, “Looks good to me. You can go plug the AC back into the boat and we’ll see if it works.” I plugged in our yellow shore cable and waited with bated breath. The inverter’s LEDs came to life and gave off a cheery glow, it had worked!

Buoyed with a new confidence, I ordered away for a DC panel, solar controller and panels, upsized alternator, and smart regulator. We’d have no shortage of power on this boat! I rode my bike to an electrical store and picked out handfuls of candy colored terminals and connectors (pink, blue, yellow) from their bulk bins. As my electrical box filled with heat shrink, crimping tools, and zip ties I began to feel like a real cruiser. While there would be plenty of trial and error ahead of us, Robin and I continued to build our electrical skills. It’s a wonderful sensation being able fix things that previously would have been thrown out and replaced. While most of the tool boxes on our boat really belong to Robin, I take great pride in my electrical kit; confident that the next time a light bulb flickers out, I will be able to fix it.

Fiona McGlynn is currently cruising in French Polynesia with her husband, Robin Urquhart on MonArk, their Dufour 35 . Fiona and Robin, in partnership with Good Old Boat Magazine, recently launched Young & Salty, a site dedicated to supporting 20-40 something sailors and encouraging other young people to take up the sport.

@youngandsalty