Blue View - The Alaska Pipeline

/

At the southern terminus of the Alaska pipeline in Valdez is a signboard that states, “The Trans Alaska Pipeline System, better known as TAPS, is an engineering marvel, a tribute to America ingenuity and hard work…”. An engineering marvel? A tribute to American ingenuity? Sure, it does run 800 miles from the Bering Sea to Valdez in the south, and sure, it does cross three mountain ranges and more than 800 rivers and streams, but, despite all that, it is only a big pipe, after all. Perhaps the pipeline marketing people got a little carried away with their superlatives?

Now, however, after we’ve traveled along the pipeline and seen firsthand the terrain that the pipeline traverses and the extreme conditions it has to withstand, I’m beginning to see their point. Not only were the logistical and organizational hurdles immense, but the problems that had to be overcome were more than a little daunting.

Take the logistical issues to for starters. The project required tens of thousands of engineers, surveyors, welders, pipefitters, heavy equipment operators, and other construction workers. There weren’t nearly enough qualified workers in Alaska, so the majority had to be recruited and enticed to relocate from the lower 48 to the far north of Alaska for up to two years. At any given time, as many as 25,000 workers were toiling on the pipeline, and for these workers, dozens of camps had to be set up, housing constructed, and roads built. Then there were all the necessary infrastructure requirements like water, sewer, commissaries, mess halls, garbage disposal, entertainment and transportation. The largest camp had 1600 workers! My mind boggles at it all.

Then there were the myriad of problems that needed solving because of the terrain and unique environment presented by Alaska:

Flexibility

Alaska is known for its earthquakes, and to make things worse, the pipeline crosses three major fault lines. In addition, because of the huge temperature swings ranging from -80° F in the winter to 100° F in the summer, the metal pipe would expand and contract as much as 5 feet per mile. Thus the rigid pipe had to have enough flexibility to cope with a major earthquake and the extremes in temperature. A straight pipe would buckle if it expanded, or rupture if it contracted. To allow for horizontal movement, the pipeline was built in a zigzag pattern, and set on sliding “shoes”. The platform itself was designed to allow for vertical movement in the case of an earthquake. Where the pipeline crosses the Denali Fault south of Fairbanks, the pipe was designed to survive a horizontal movement of up to 20 feet horizontally and 5 feet vertically.

The engineering was given a real-life test in November, 2002, when a 7.9 earthquake struck the Alaska Range. The quake ruptured the earth for almost 200 miles along the Denali Fault, and where the pipeline crossed the fault, it shifted 7.5 feet horizontally and 2.5 feet vertically. While there was some damage to the support structures, the pipeline survived without spilling a drop of oil.

Crossing Mountains

The pipeline crosses three mountain ranges, including the impressive Brooks Range. Laying the pipe up and over an extremely steep, high range of mountains in arctic conditions is non-trivial. Just think back to the last paragraph regarding flexibility. How do you support a mile long section of zigzagging pipe up a 50° incline while maintaining the needed flexibility without the whole thing sliding down the mountain? Beats me, but they did it. Add to this the necessity of avoiding avalanches, flash floods, wildfires and rock slide areas (or designing the pipeline so it could withstand these potential disasters), and the task becomes even more difficult. Once the pipe was in place, pumping stations had to be built at the base of each range to force the oil up and over the mountains, and something else that hadn’t occurred to me, additional pumping stations had to be built on the downhill slope to slow the oil flow on its way down.

Permafrost

In much of Alaska, the top couple of feet of soil freezes in the winter and thaws in the summer. Below this layer, the soil stays frozen, never thawing, and is known as permafrost. The permafrost may extend downward a few feet or as much as 1500 feet from the surface. The permafrost is quite stable unless it thaws, in which case, as the ice in the soil turns to water, the soil sinks. The low spot then collects water, and when it refreezes the following winter, swells back up, higher than its original level. This played havoc with Alaska’s early roads that were often built right on top of the permafrost, as the warmer road surface, coupled with culverts dug into the permafrost accelerated the thawing of the permafrost. Newer roads are built with many feet of insulation and gravel over the permafrost to prevent, or at least reduce the likelihood of the permafrost melting and the resulting frost heaves, sink holes and sagging low spots.

Surprisingly, pipeline oil is often very warm, sometimes reaching temperatures of 140° F. In most other parts of the world, oil pipelines are usually buried, and the oil, becoming less viscous the warmer it gets, is easier to pump. Burying the pipeline in the permafrost, with its continual flow of warm oil, however, would cause significant thawing, which, in turn, would cause the pipe to sag. Instead, throughout most of the permafrost region, the pipeline was built on platforms above ground. This, of course, introduced a host of new problems: the pipeline had to be high enough so as not to impede migratory routes of animals such as caribou; expansion and contraction due to the temperature extremes had to be allowed for; the pipeline had to withstand the many wildfires that occur each year; and the footings for the platforms would need to prevent the transfer of heat into the permafrost to keep it from melting.

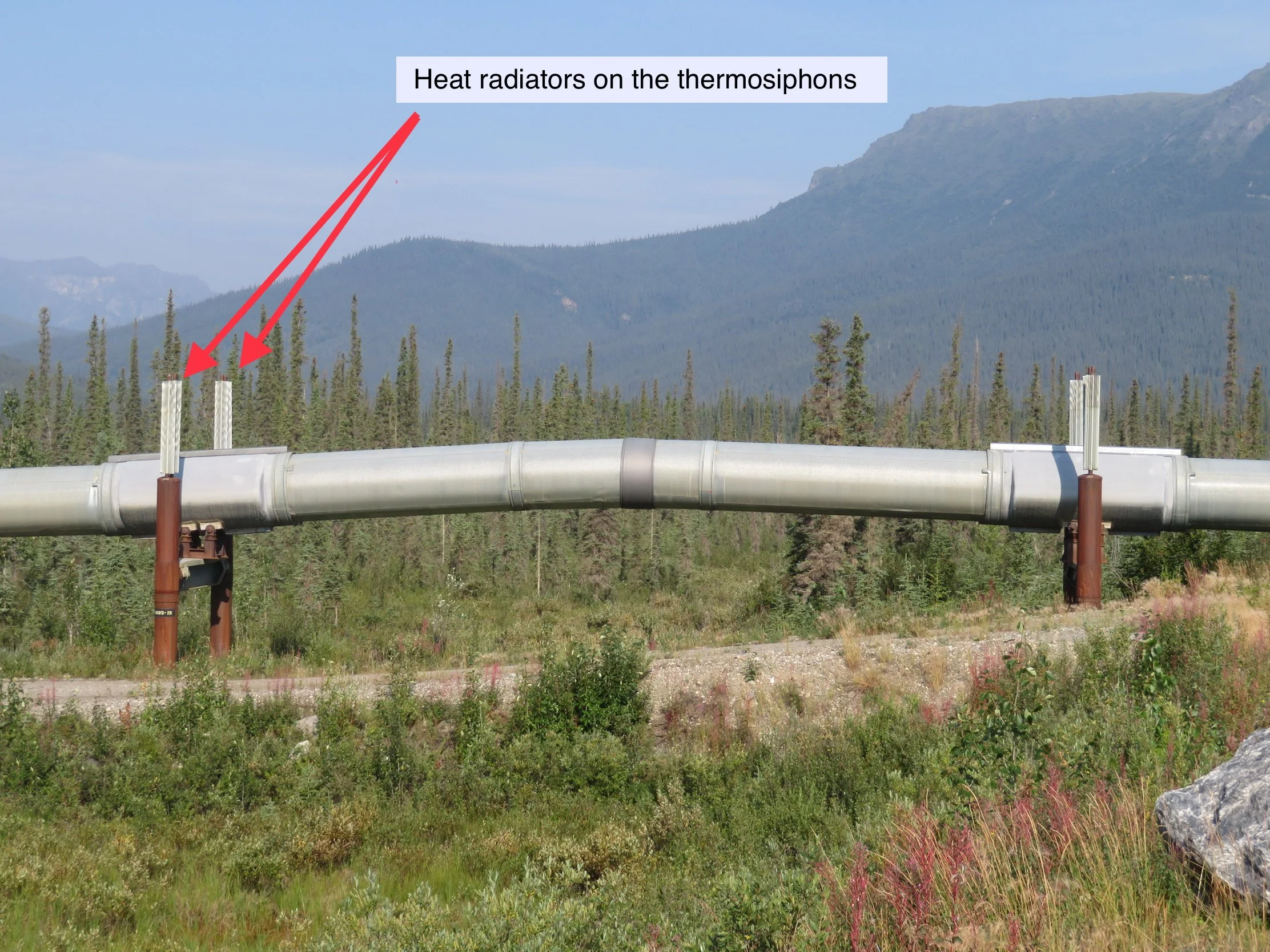

The latter problem was solved rather ingeniously. Engineers built “heat pipes” or “thermosiphons” into the support legs that transfer heat from the permafrost to radiator fins exposed to the air. The heat pipes are filled with liquid ammonia refrigerant that changes from a liquid to a gas at around 30° F. If the permafrost warms to that temperature, the liquid vaporizes, removing heat, then rises to the top of the pipe, where the radiator fins disperse heat from the gas to the surrounding air. When the air is cool enough, the refrigerant returns to a liquid state, then drips back down to the bottom of the pipe and repeats the process. More than 120,000 heat pipes were installed on the pipeline.

Wildfires

To withstand wildfires, the pipeline is wrapped in insulating glass, then an outer sheathing of galvanized steel. In addition, the entire raised portion is continually cleared of brush.

Cleaning and Examining the Pipe

Oil contains wax, water and other contaminants that adhere to the inside of the pipe which, like arteriosclerosis in the human body, eventually restrict flow through the pipe. To clean the pipe interiors, large mechanical devices called pigs are periodically put inside the pipe. As the oil pushes them along, they remove the contaminants inside the pipe.

There are also “smart” pigs that incorporate a host of instrumentation to analyze the condition of the pipe. These can measure wall thickness, detect corrosion and spot dents, bends, movement, sagging areas and other anomalies in the pipe before they become problems. About the only thing they can’t do is oink.

Aurora Borealis

One last, rather unique problem that had to be solved is one my fellow nerds will appreciate… galvanic corrosion due to the Northern Lights. The Aurora Borealis causes electromagnetic waves in the atmosphere. As an electromagnetic wave passes through a conductor, like a steel pipe for example, it induces an electrical current in the conductor. The current tries to find a path to ground, and if the path is through an electrolyte such as water, the pipe will rapidly corrode. The buried sections of the pipe are particularly susceptible to this galvanic corrosion.

To prevent it, sacrificial anodes are used. Any boat owner knows about anodes or “zincs” as they’re sometimes called. If a less noble metal, i.e. a metal lower on the periodic table, is electrically connected to the steel pipe, the current will pass through it to ground, and the anode will corrode instead of the steel. Zinc is the metal most often used for sacrificial anodes, and on the buried sections of the pipeline, zinc strips are electrically connected to the pipe to prevent galvanic corrosion. Other than the engineers designing the pipeline, who knew that the Northern Lights could corrode pipes?

Pipeline Report Card

The pipeline was completed in 1977, and I think I’d now agree that it was truly “an engineering marvel [and] a tribute to America ingenuity and hard work” to build it. But let’s fast forward to 2023 and see how well it has done in those intervening 46 years.

Spills

While access to the pipeline is controlled to some extent, it is not feasible to totally restrict access to all 800 miles of it, if for no other reason than it would block animal migration routes. As we traveled along the pipeline, there were literally hundreds of places that we could have driven to and/or walked right up to the pipe. Thus, in addition to acts of nature that could cause the pipe to rupture or leak, there is a real possibility of human caused damage to the pipe, due to an accident, because of criminal mischief, or from acts of terrorism.

If a spill does occur, there are 170 valves along the pipeline, some to prevent back flow and others that can be operated remotely to shut off the oil. In addition, there are a number of fast response teams strategically located that can respond within minutes to emergencies, either by road or by helicopter.

These measures can help reduce the severity of a spill, but not before a lot of oil is leaked. For example, in 2001, an inebriated man shot a hole in the pipeline with a hunting rifle. It spilled 285,000 gallons of oil before the pipe could be patched. Another example was in 1978 when an explosive charge blasted a hole in the pipe, causing 675,000 gallons to spill onto the tundra. In the past 22 years alone, there have been more than 18 breaches in the pipeline, spilling at least 550,000 gallons of oil.

The Future

The pipeline is facing a much larger problem than sabotage, however. Alaska is heating up twice as fast as the global average, causing large areas of the permafrost to melt. In 2021, the supports for an 800 foot section of the pipe began to twist and bend as a large area of the supporting permafrost began thawing and started sliding downhill. The Alaska Department of Natural Resources authorized the installation of 100 thermosiphons in the area around the pipeline to help refreeze and stabilize the permafrost. As global warming continues to thaw the permafrost, though, we can expect many more similar problems, with an increasing likelihood of a major spill.

This underscores an obvious irony. To quote Inside Climate News: “The oil industry must act to keep the permafrost frozen to maintain an infrastructure that allows it to extract more of the fossil fuels that are causing the warming”.

I’m hoping that today’s generation of engineers and scientists can find “an engineering marvel and a tribute to America ingenuity and hard work” that begins to reverse global warming… whether it be cheaper, safer nuclear fission, a workable nuclear fission, an economic, large scale method of storing and transporting the power produced by alternative energy sources, a method of scrubbing carbon dioxide from the atmosphere, or something no one has thought of yet, and that the Trans Alaska Pipeline becomes an interesting relic of the past.

See you next week…