The Blue View - Outboard Maintenance

/Our two-stroke dinghy engine has been sitting, unused, on the stern rail for almost a year now, and before we set out for points west, I thought it prudent to do some preventative maintenance. As with most things aboard, it's much better to find any problems now, in the comfort of a marina with chandleries and hardware stores close at hand, than later in some isolated anchorage.

Gasoline engines, in particular, don't like to sit unused for long periods of time. Leave the engine sitting in a saltwater environment, and it is bound to be unhappy. In my experience, the two biggest issues will be the fuel and all the mechanical parts that, if not actually seized up, don't work as smoothly as they should.

Here is my checklist:

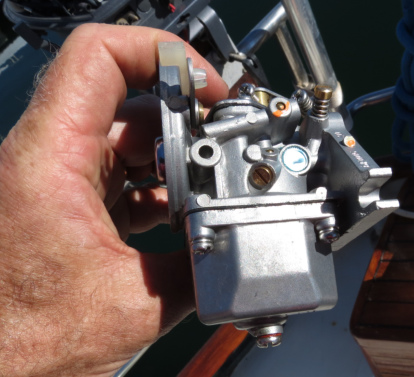

- Carburetor. Gasoline evaporates, and as it evaporates it leaves a varnish like residue, especially gasoline with two-stroke oil added. This residue will quickly clog and/or gum-up the carburetor needle valve and jets. Before I even think of attempting to start the engine, I pull the carburetor, remove the float bowl and clean it out. This process, even with my fat fumbling fingers, takes 15-20 minutes and will save a whole lot of time later if the jets get clogged. While the carb is removed and partially dismantled, I give it a good visual check - does the float look good, is the needle valve sticking, do the gaskets look good, etc.

- Fuel Pump. If the carburetor float bowl had any residue, more than likely the fuel pump will as well. I dismantle it and clean and inspect the various membranes and gaskets.

- Fuel Filter. My 4 HP Yamaha uses a small disposable fuel filter. I replace it annually, if the engine has been sitting unused for awhile, or if the engine is showing the symptoms of a clogged filter. One symptom of a partially clogged filter is the engine coughing and dying after running at high RPMs for a few minutes.

- Fuel. While the fuel filter is removed, I decant a cup or so of fuel from the fuel tank into a clear plastic bottle. If there is any water in the fuel, it will sit on the bottom of the bottle, and any dirt or rust in the fuel will be quite apparent.

- Anode. I check the anode and replace if necessary.

- Lubrication. I check and lubricate all the mechanical linkages and moving parts... shift linkage, mounting handles, tilt lever, throttle control cable, etc. Everything gets cleaned, lubed and exercised.

- Spark Plug. I remove the spark plug (there's only one on our 4 HP) and clean or replace it.

- Wiring. I check all the electrical connections and wiring for chafe and corrosion, and make sure everything is secure.

- Prop. I check the propeller for damage. We can live with the usual dings and scratches, but it should be replaced if there is any significant damage. I keep a spare aboard just in case.

- Gearbox. I change the gearbox oil annually.

- Lifting Straps. Marcie made a cover with integral lifting straps for the engine. I check it all to make sure the stitching hasn't disintegrated in the sun and the straps are secure and look good.

- Mounting Pad. As long as I'm spending all this time checking the engine, I inspect the rail mounted pad that holds the engine on the stern rail to make sure it is still secure.

- Test Drive. The only thing left to do is mount it on the dinghy and take it out for a spin around the neighborhood. Ours started on the second pull, which is always very satisfying. After the test drive, if there is any chance the engine will be unused for more than a couple of weeks, I shut the fuel off and let the engine continue to run until it runs out of gas in the float bowl and fuel lines.

Spares

For spares, I keep the following on hand:

- Propeller

- Spark plug

- Fuel filters

- Impeller

- Carburetor rebuild kit

- Pull cord

- Throttle cable

- Gearbox oil

- Anode

And when all else fails we still have the backup system...our trusty oars