The Blue View - A Simple Project?

/ One of the items on my to-do list was to replace the galley freshwater foot pump. We have pressurized water for the freshwater system, but fresh water aboard the boat is precious, and we try hard to conserve it. When a constant stream of water is not required, like when brushing teeth or washing hands, a pump or two on the foot pump sends a long squirt of water to the faucet above, and provides just the right amount of water without wasting much at all. Our foot pump died while enroute from Puerto Rico to St. Augustine, FL, and it's been on the repair list since then. Now that we are tied up next to a boatyard in Chesapeake, VA, I am finally getting to it.

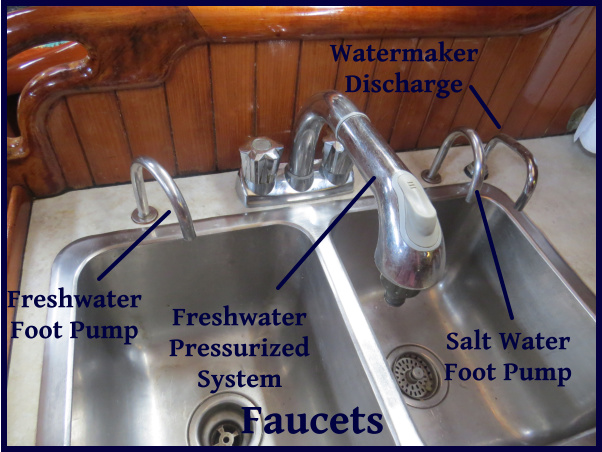

One of the items on my to-do list was to replace the galley freshwater foot pump. We have pressurized water for the freshwater system, but fresh water aboard the boat is precious, and we try hard to conserve it. When a constant stream of water is not required, like when brushing teeth or washing hands, a pump or two on the foot pump sends a long squirt of water to the faucet above, and provides just the right amount of water without wasting much at all. Our foot pump died while enroute from Puerto Rico to St. Augustine, FL, and it's been on the repair list since then. Now that we are tied up next to a boatyard in Chesapeake, VA, I am finally getting to it.

It shouldn't have been much of a problem – just disconnect the hoses and remove four screws to take the old pump out, then reverse the process to install the new one. Simple – an hour, maybe two at most. Except, as our readers have heard on more than a few occasions, nothing's ever easy on a boat.

To begin with, the old pump is original equipment on Nine of Cups, and the same model is no longer available. The newer models are almost the same size, but the hose connections are not in the same place. Okay, add an hour or two to re-plumb the hoses.

As I was removing the pump. I discovered a couple of things: 1. The bulb in my task light had burned out. No problem – I'll order a new one on Amazon and use my “mouth-operated” task light in the meantime, and 2. there were several hose clamps that were overdue to be replaced. After checking my stock on-board, it became evident a trip to the chandlery was in my future. May as well replace the hoses at the same time. Add another hour and $35 to the job.

While removing the screws, it became apparent that the mounting block under the pump was somewhat dodgy. I probed it with a screwdriver and discovered it was wet through-and-through and delaminated, so it would need replacing. We also have a seawater foot pump mounted next to the freshwater pump. It is currently working, but the block supporting it also appeared to be deteriorating. Add four hours to R&R the other pump, then fabricate, seal and paint both mounting blocks.

But wait... as I was removing the mounting blocks, I noticed that the floor under the sink had a few soft spots. I investigated this to find some delamination problems with it as well. I could just ignore it and plan on doing it in a year or two, but since I now had the pumps and mounting blocks all removed, I might as well do it all now. Add a couple of hours to remove the old floor, then a couple more to fabricate and fit a new piece of plywood, plus a couple of hours to epoxy it in place, then seal, prime and paint it with two coats of marine enamel.

And as long as I'm painting the floor and the mounting blocks, I should repaint the rest of the area under the sink as it's starting to look a bit worn. Of course, I'll have to remove a few more things before repainting, like the filter assembly for the watermaker, and, oh, look there – the bracket holding the filter in place is all corroded underneath. Shouldn't take more than 2-3 hours to locate or fabricate a new bracket and fit the filter to it.

Finally, to add injury to insult – literally – I cut my head on a hose clamp on the sink drain as I was leaning in to remove the filter bracket. But that's to be expected; rarely is a project completed aboard Cups without shedding at least a little blood.

So now we're up to 18-20 hours – if nothing else goes wrong – for this simple, 1 or 2 hour job, and it's definitely cutting into my afternoon nap time. I'm really glad this wasn't anything complicated