The Blue View - Whisker Pole Repairs Pt. 2

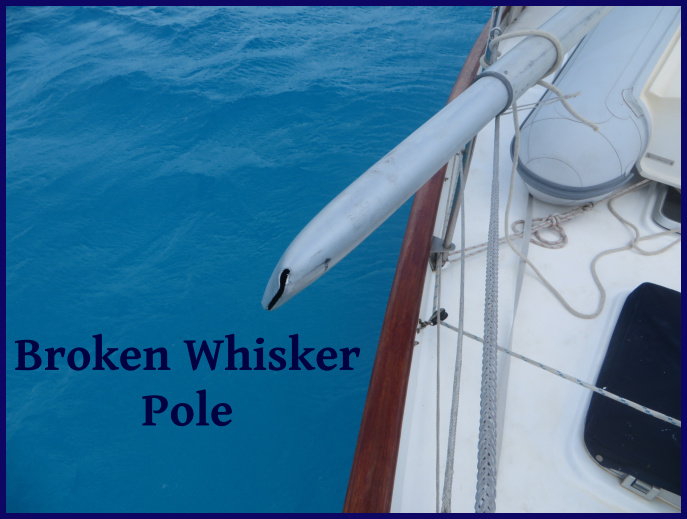

/On our last day en route from Geraldton, Western Australia to the Cocos Keeling Islands, we broke our whisker pole. It was entirely my fault. I was hand-steering Nine of Cups, something that is necessary when we are sending and receiving emails via HF radio (our autopilot causes too much radio interference). We were sailing almost downwind, and a combination of a moment's inattention coupled with a large, unexpected wave caused us to jibe. Before I could react, the poled out genoa started flogging, and in a flash, our 28-year-old whisker pole broke in half. BAM!

Our whisker pole is a telescoping Forespar pole, and it was the inside tube that broke. I cut the bent and broken section off the end and put it back together as best I could. It actually held together all the way to Durban - another 4000 miles or so. It did have a few issues, however. The toggle on the end that attaches to the mast was so badly bent that the pole could not be stowed on the mast, and we had to remove the pole and lash it to the lifelines whenever we weren't using it. Also, the small aluminum tube inside the pole, called the stinger, had more bends and “s” shapes than straight sections, making it very difficult to extend or retract the telescoping portion of the pole.

Now that we are in Durban, I wanted to repair it properly. I was able to find a new length of aluminum tubing in the right diameter to replace the stinger. I cut it to size, drilled the necessary holes and fitted it into place.

Unfortunately, I can never seem to accomplish any task on Nine of Cups without a little drama. The pole has three large bushings that guide and constrain the inner tube when it is extended. While I was maneuvering the 24 foot pole on the finger pier next to Cups, I managed to lose one of these bushings. It slid off the end of the tube, bounced twice, then rolled unerringly off the side of the finger pier into the drink, never to be seen again. The good news is that I found a very competent and inexpensive machinist who was able to fabricate a new bushing for me. Now the pole extends and retracts better than it ever has.

The bent toggle was a bigger problem. The Forespar literature says that the toggle can be removed by pressing the pin on the side of the end fitting. In the 15 years we have owned Cups, I have never been able to budge this pin. I have heated it, cooled it and used all sorts of heavy tools and weaponry encouraging it to move – all to no avail.

Since I couldn't remove the old toggle, my machinist friend wasn't able to make a new toggle, but he was able to straighten the toggle in situ. The pole now rotates nicely side to side and stows against the mast as it should. Despite assurances to the contrary from the machinist, however, I am somewhat concerned that the metal might have been weakened when the toggle was bent and then straightened. It might be time to think about a new pole when we return to the U.S.

In the meantime, I welcome input from anyone who has suggestions on getting the pin to move and/or removing the old toggle. Any ideas out there?