The Blue View - Keeping Busy

/Marcie and her sister Lin have a very enviable relationship. Although they are 11 years apart, they are as close as twins. They don't look alike, but do share many of the same mannerisms and have very similar personalities. They're inseparable when we visit Boston, and their farewells are always tearful when it's time to return to Nine of Cups. They also sound alike on the phone. In our early days together, if I was out and about and called the home phone, I sometimes thought I was talking to Marcie when, in fact, it was Lin I was talking to. Lin was all too happy to play along, and it sometimes led to some embarrassing conversations. Now I've caught on, and if I'm not sure which sister I'm talking to, I use my own set of 'security questions' – “Where do we keep the UHT milk on Cups?” or “What unusual anatomical feature do I have on my backside?”.

We aren't in Boston all that frequently, so when we are, the sisters spend a lot of time with each other catching up, and I've found that it's best if I find a project to immerse myself in. Sometimes it's a household project that Lin has been saving for me from her to-do list – install some motion-activated lights on the back steps or clean out and reorganize the garden shed. This time, however, there were no pressing household projects, and I have time to complete the design of our new wireless windlass controller.

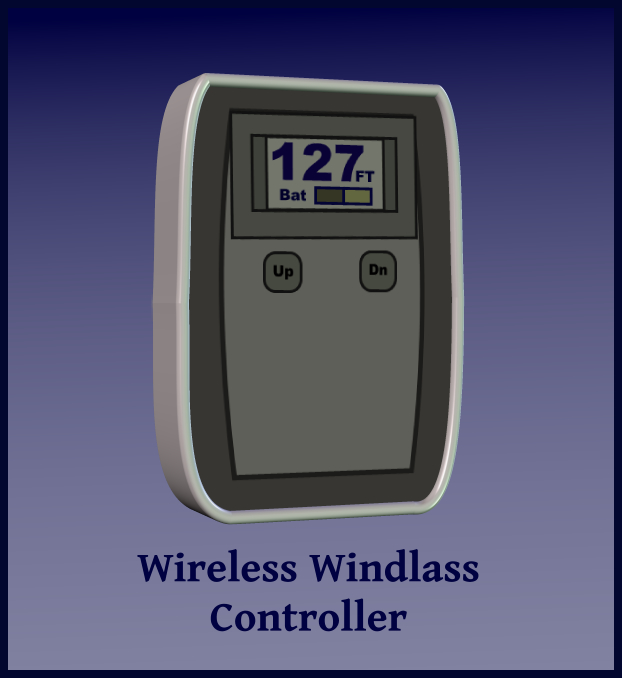

The design will consist of two modules – the handheld, battery- powered module and the controller module located in the forepeak locker, close to the windlass. The controller starts and stops the windlass and keeps track of windlass revolutions. The handheld module monitors the Up and Down buttons and displays the amount of rode deployed. The two modules communicate using matching RF transmit/receive radio modules.

I've been working on the handheld module, and it's coming along nicely. It is quite small and incorporates a sunlight readable, graphics display (one of the shortcomings of the previous design was that it was hard to read in the bright tropical sun). The wireless range (500 meters) should be more than adequate for our use – we rarely try to lower or raise the anchor from shore.

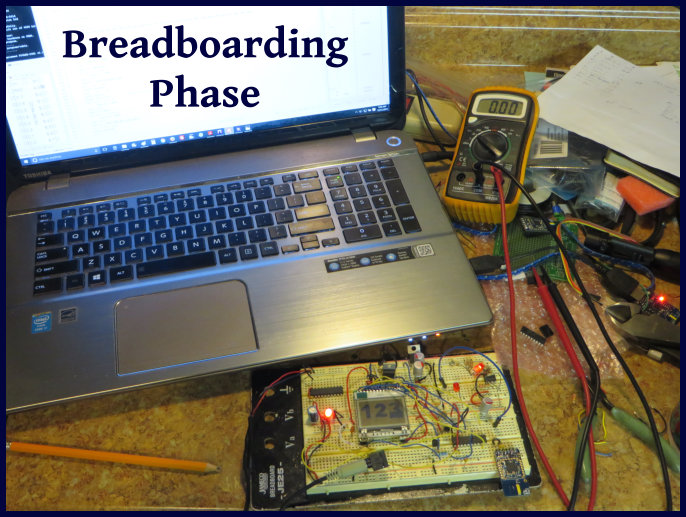

I've finished most of the breadboarding phase. I am using a prototyping breadboard to connect all the components, get everything functional and working, and to work out any hardware issues. As of today, the display is functioning and I'm able to communicate wirelessly between it and a wireless transceiver connected to my laptop. I'll start the fabrication phase next. Lin provides me a place to work, a few handy tools like a drill press, and all the power I can use, so I want to take advantage of it while I'm here. It's much more convenient than using the Nav desk aboard Cups as a workbench and having to rely on solar and wind to power my soldering iron.

After the handheld module is built and functional, I will build the control module. This part of the design, other than the wireless communication, will be similar, to the previous design. The old design had a tendency to occasionally reset with the large electrical spikes that are generated by the windlass motor, so I will enhance its noise immunity in this version. The last phase will be to perfect the communications protocol between the two modules and complete the user interface software.

When it is finally complete and tested, I'll provide the design details to anyone who's interested.