The Blue View - Annual Engine Maintenance

/As the title suggests, it was time to spend a day doing all those engine tasks that have to be done at least once a year. This is certainly not my favorite way to spend the day, but I prefer to get them all out of the way at once. Adelaide was going through a heat wave and trying to work topsides in temperatures well over 110F/43C didn't seem like a good plan, so today was the day. I go through each system of the engine, starting with the cooling system. Nine of Cups has a Ford Lehman diesel engine, which is a marinized version of a Ford tractor engine. It has a freshwater cooling system, but instead of a radiator, it uses a heat exchanger to cool the freshwater coolant. There are actually three heat exchangers, one for the engine coolant, one to cool the motor oil and one to cool the transmission fluid. Raw seawater is pumped through a strainer by an impeller type pump, then through the three heat exchangers. The seawater is then mixed with the engine exhaust, which cools the exhaust gases and acts as a muffler.

These are the items on my cooling system checklist:

- Finger zinc. The first heat exchanger has an internal finger zinc to prevent corrosion. I usually check it quarterly.

- Raw water strainer. This occasionally gets clogged and is checked as needed, but I pull it out and inspect it for fouling and corrosion annually. While it is out, I open the thru-hull briefly to flush out anything in the intake line.

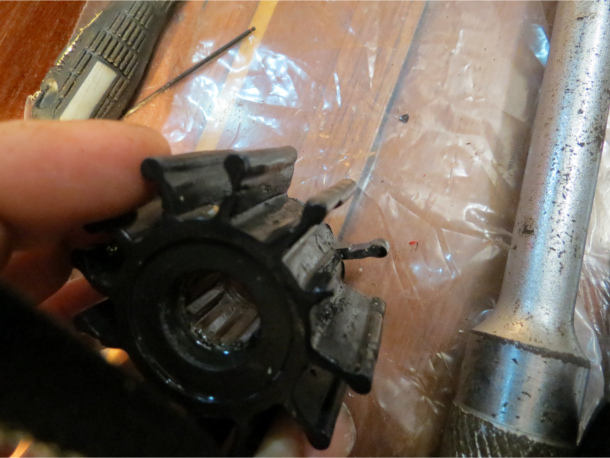

- Impeller. The impeller will usually last for years unless something finds it way through the strainer or the engine is run without water. This is what happened when I tried to start the engine before cleaning the thru-hull, and sure enough, it was damaged.

- Coolant heat exchanger. This heat exchanger has a tendency to clog up. I remove the end cap and run a small wooden dowel through each of the holes and clean any debris from the inlet side. I replace it every five years.

- Oil and transmission heat exchangers. I inspect these externally to check for corrosion and to make sure the oil lines feeding them are secure and in good shape. I replace these every three years.

- Hoses and clamps. All the hoses and clamps in the cooling system are checked and replaced as needed.

- Exhaust mixer. We have a monel exhaust mixer that cools the exhaust gases and acts as the muffler. This is inspected to check for corrosion and integrity.

- Exhaust hose. We have a 10 foot or so run of hose from the mixer to the transom, and this is inspected to check for aging or chafe.

Fuel System

The fuel system checks are next. Fuel is pumped out of either the port or starboard fuel tank, through a primary Racor filter, then to the day tank. From there, it is gravity fed to the secondary filters and on to the injector pump. These are the items on my fuel system checklist:

- Fuel tanks. I Inspect each fuel tank to check for sediment or algae. Polish the fuel if necessary.

- Primary filter. I change the filter and clean the sediment bowl.

- Day Tank. The day tank is inspected to make sure it is secure and there is no evidence of leaking.

- Secondary filters. Both of the secondary filters are replaced.

- Hoses and clamps. All hoses and clamps are inspected and checked for aging, corrosion or wear.

- The fuel system is then bled and the engine is started and run until warm.

Oil

- Normally the oil and filter is changed every 180-200 hours. Since the oil hadn't been changed in over a year, I changed it and the filter. All oil lines are inspected.

Transmission

- I change the transmission oil annually. The old oil is inspected for evidence of water or overheating. All the transmission lines are inspected. The engine is started and the transmission is put in gear, both forward and reverse to check operation and controls. Shaft vibration is checked for evidence of engine misalignment.

Coolant

- The coolant level is checked. I flush and replace it every two years.

Engine cables and controls

- The engine is controlled by cables that run from the cockpit to the engine room. These are checked for damage or corrosion. The fittings on each end are inspected.

Air filter

- The air filter is cleaned and checked.

General checks

- I give the engine a good once-over to check for the following:

- Motor mounts. All the motor mounts are checked for tightness. The port side aft motor mount has a tendency to work loose on Cups.

- Oil leaks. Any oil leaks are investigated.

- Valve cover bolts. The valve cover bolts are checked and tighten.

- Engine belts. Our engine has two belts and these are checked for aging and tightened or replaced, if necessary.

- Visual. I check the wiring, starter, solenoid, alternator, water pump, injector pump, etc. for any visual indication of problems.

Clean Up

This is the home stretch.

- I wipe down the entire engine and touch up any paint that has worn away or is bad shape. It is much easier to find a future oil leak if the engine is clean.

- After changing the oil and fuel filters, bleeding the fuel lines, and flushing the raw water intake, the engine sump always has several inches of a melange of all the engine fluids. I sop up all the petroleum based liquids using oil absorbent pads and dispose of it properly. The remaining liquids are a combination of seawater, fresh water and possibly engine coolant. These are cleaned up and disposed of, and a fresh oil absorbent pad is placed in the sump. Our engine always leaks a small amount of oil from the various seals, and the pad collects it.

Me

- By now, I am a stinky, sweaty, oily mess. The best part of the entire job is taking a shower, changing clothes and updating my maintenance log with a cold, home brewed India Pale Ale.