The Blue View - Securing the Floorboards

/I was perusing a cruisers' forum a couple of days ago, and I came across a thread that was discussing methods of securing the floorboards on a sailboat. In each area of the boat, like the salon, galley, and cabins, there are removable floor sections that allow access to the area below the sole. This is technically the bilge area, but in many sailboats, it is also used for fuel and water storage tanks, as well as storage. On Nine of Cups, these areas are home to our tanks as well as several pumps. It is also used to store canned goods, small batteries, gallon jugs of engine oil and coolant, and several odd shaped tools and spares. One section is devoted entirely to hoses and tubing.

Normally, the floorboards stay in place quite well on their own. It takes a major knockdown, or worse, a rollover or pitch-pole to dislodge them. If that should happen and the floorboards were not secured, there would be flying hunks of wood, cans, pickle jars, and large tools everywhere. If we weren't badly injured from the rollover, getting battered by a spare water pump and half a dozen cans of beans would probably do the trick. Then, if and when the boat righted itself again, the crew and all the other flying cannonballs would be flung back towards the now gaping holes in the floor. Not a pretty picture.

The thread was quite long, and most of the entries were rather flippant – something like “Try keeping your boat upright...that's always worked for me. Haw – haw”. I guess if the writer is a coastal cruiser, the possibility of a major knockdown or rollover is pretty remote. But I think to most serious offshore sailors, especially those that venture into the high latitudes, these events are real possibilities. Hence, the question of how to secure the floorboards was perfectly valid in my opinion.

When we bought Nine of Cups, I dreamed of sailing to some of these remote parts of the globe, and I felt it was important to make Cups as safe as possible. This included finding a method of securing the floorboards. I had several criteria in mind. We access the storage areas under the sole frequently – sometimes several times a day. In addition, some emergencies require immediate access to the bilge. If we suddenly start taking on water and need to close a thru-hull, for example, it is important to be able to get to it quickly. Thus, the method of securing the floorboards should be quick and easy to engage and disengage. A second criteria was that it not be too expensive. We have 16 floorboards, so the costs add up quickly. It should also be fairly quick and easy to install. If each of the 16 floorboards takes several hours to install, the project would take a long time to complete. Finally, the system should look good. The interior workmanship on Cups is quite beautiful, and despite my innate clumsiness and irritating propensity to add dings and divots to the woodwork, I try not to intentionally damage it.

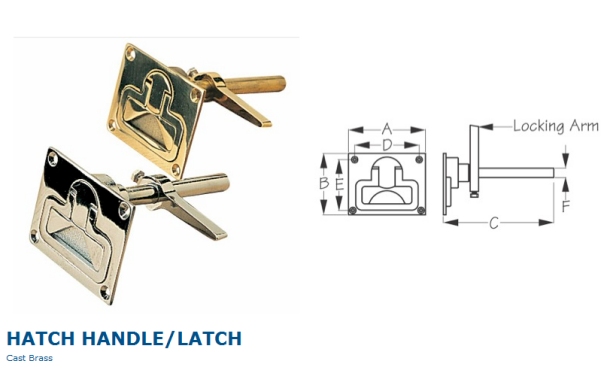

I found several possible solutions, but most did not meet all my criteria. There are some elegant handles that sit flush, and twist to lock the floorboards in place. These are expensive, require a fair amount of time to install, and since the floorboards already have lift rings that wouldn't match the new hardware, it wouldn't look all that great. Other than that, they were perfect.

PYI has some nifty little floor anchors made for the purpose. They lock with half a turn using a screwdriver and they look good. The only problem is that I would need 2 to 4 for each floorboard, and at a price of about $15 each, the total cost for the quantity I needed plus the installation tools would have been about $800. That was quite a bit more than I was hoping to spend.

I was still pondering the problem when a friend on another boat offered a solution he had seen using bungee cord. It sounded like a gimcrack solution, but he thought it was used by the Swedish manufacturer Hallberg-Rassey on its production boats. I was never able to verify this or to see exactly how they implemented their version, but the idea turned into a workable solution.

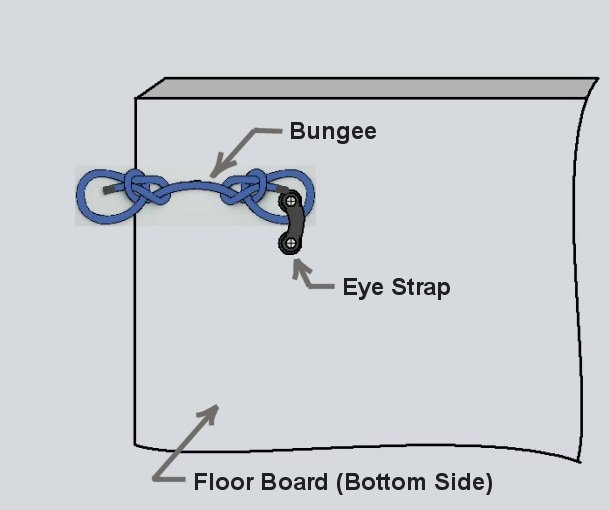

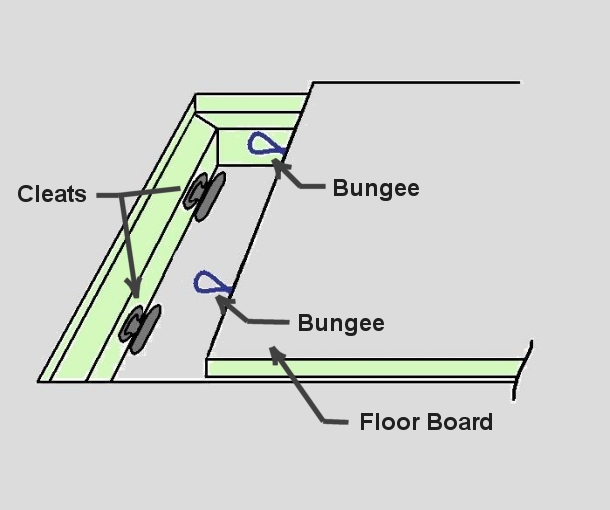

I started with a short length of 3/8” (10mm) bungee cord with a loop on both ends. Initially I secured the loops with crimps, but later found that just tying a bowline in each end worked just as well. One end was permanently attached to the bottom of the floorboard with a strong eye strap. A small cleat was attached to the side of the stringer that supports the floorboard. I made the length of the bungee just long enough to loosely reach between the eye strap and the cleat. I attached two bungee cords, to each end of a floorboard.

Before proceeding any further, I wanted to test the strength of the system. I found a couple of 6”x 10” timbers, placed them on the ground spaced slightly further apart than the length of the floorboard, and held them in place with some rocks. I screwed four cleats into the timbers, then attached the floorboard to the timbers by looping the ends of the bungee over the cleats. Then I stood on the floorboard. The bungee cords stretched a a few inches, but held fine. Then I piled about 20 pounds of miscellaneous objects onto the floorboard and stood on it again. It held the combined weight of 200 pounds without a problem.

Once I was convinced the system was strong enough, I wanted to see how difficult it was to attach the bungee cords to the cleats under the sole once the floorboard was in place. I found that if I lifted the floorboard enough to get my hand underneath the end, it was not difficult to stretch the bungee cord and attach the loop to the cleat. With a little practice, it takes only a second or two to attach or detach each bungee cord.

For smaller floorboards that have nothing heavy stored beneath, I attached two bungee cords, one on each end. For larger floorboards, or those with heavy items stored below, I attached four bungee cords, two at each end. I melted the ends of each bungee cord to keep them from unraveling, then covered the ends with shrink tubing. When making a loop using a bowline, I found it held well as long as I applied enough tension to ensure the know was quite tight.

Part of our pre-departure routine when we set out on a long passage is to secure all the floorboards. It only takes a few minutes to attach all 16 floorboards. We check them again if a gale or storm is headed our way. We have suffered only one knockdown in all our passages, and none of the floorboards budged. While this was not a really good test of the system, like our liferaft, ditchbag and EPIRB, we dearly hope that we never have the opportunity to see how well it really works.