The Blue View - What Broke?

/The passage across the Great Australian Bight was pretty benign, all things considered, and we are counting our blessings. This stretch of water can be quite difficult, but we found places to tuck into when the wind wasn't cooperating. Benign or not, however, we had the usual list of items that needed attention or repair enroute or when we arrived in Esperance. The old, oft used adage that the definition of cruising is making repairs in exotic locations couldn't be more accurate.

Here is our list:

1. Shaft Seal. The propeller shaft seal tops the list. While were sailing along briskly at 7 knots or so on our last leg to Esperance, Marcie noticed that the bilge pump light was on. We have an indicator light located in the cockpit that lights up when the bilge pump is running. The automatic bilge pump rarely comes on unless we are taking a lot of water over the bow or there is a leak somewhere. Since we weren't taking any water over the bow, and the light was staying on, it was something that needed checking into – sooner than later.

After pulling up a few floorboards, I found the source, which was the prop seal. The propeller shaft is connected on one end to the back of the transmission, then extends about 3 feet (1m) or so where it passes through a hole in the hull to the cutlass bearing and then the propeller. There is a seal between the shaft and the hole that usually keeps the water on the outside of the boat. This seal consists of a substantial stainless steel disk that is attached to the shaft and a synthetic rubber bellows that is attached to a collar around the hole in the hull. To make the seal watertight, the disk is slid down the shaft until the bellows is compressed somewhat, and then the disk is locked in place using set screws (or grub screws for you non-Yanks).

The disk on our shaft had worked its way back up the shaft, no longer making a seal with the bellows, and was now leaking copious amounts of water. The fix was simple and completed in about an hour – loosen the set screws, coax the collar back into place with a hammer, pry bar and large screwdriver, then tighten the set screws. There was a slight complication because the shaft was spinning due to the flow of water against the prop, but once Marcie reefed us down and slowed the boat to about 3 knots, I was able to stop the prop and lock it in place using locking pliers. (Nine of Cups has a shaft brake, but I had removed it some time ago while I worked on a shaft generator – a project that is still in the works). It is a little disconcerting that the set screws were tight and the disk still slipped along the shaft.

So, add to the to-do list:

2. Put the shaft brake back on the shaft; 3. Figure out a way to make sure the disk doesn't slip again (maybe use a shaft anode?); and as long as I'm putting the shaft brake back on, I might as well (4.) check the engine mounts and (5.) engine alignment.

6. Jib Clew. The clew came loose from our 90% jib and needs repair. The old 120% genoa is back in place and doing well, but add the jib repair to the list.

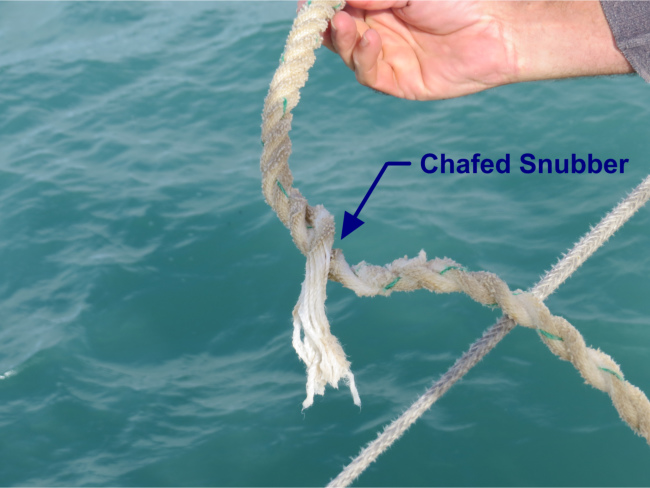

7. Snubber. The anchor snubber chafed part way though while anchored in Eucla. I replaced it with a fresh line.

8. Main halyard shackle. The shackle that connects the halyard to the mainsail was bent and was replaced en route.

9. Whisker Pole. The wire attached to the jaw release on the whisker pole is corroded and needs replacing. Also, the (10.) topping lift and uphaul lines need to be marked to indicate the correct height for the 120% genoa.

11. Chartplotter/GPS. Our seven year old cockpit chartplotter and GPS died. It would simplify things if we could buy the same model, but is is no longer available. It appears all the new gear either won't talk to our other electronics or it is a different size, meaning the teak panel on which the current one is mounted will have to be modified or replaced. Meanwhile, one of the handheld GPS's, the nav station chartplotter and the Navionics App on the iPad is getting us by.

12. Chain Stopper. Once the anchor is deployed, the chain stopper locks the anchor chain in place and takes the load off the windlass until I can get a snubber attached. Ours is showing some wear and should be replaced.

13. Leak over Nav Station. There is a leak over the nav station, and we are getting a drip during hard rains or when we take a lot of water on deck. Not sure whether it is the deck prism or porthole above the area. Needs to be investigated and repaired.

14. Staysail furler. The staysail furler line needs adjusting.

15. Stern Light. One of the cable ties securing the electrical wire that powers the stern light has broken and needs replacing. Meanwhile, the wire is hanging loose and is sure to get snagged by something if it isn't corrected.

16. Dinghy Leak. The inflatable continues to leak water. This is more of an annoyance than anything, as the groceries and backpacks get wet as we transport them. It looks like it is a seam on the starboard side, but my previous attempts at patching the likely spots hasn't corrected the problem. I'd welcome any ideas on how to isolate a water ingress problem on an inflatable.

17. Water Tank. We have some contamination in the starboard water tank. When we fill a clear water bottle, there is quite a bit of sediment in the water. It probably won't hurt us, but is somewhat unappetizing. Probably something we picked up from a water fill somewhere along the line, and now that we are churning up the tanks during our passage-making, it is being passed along. Time to clean out the tanks, but in the meantime we will start filtering our freshwater.

Seventeen items... that's probably pretty average for 3-4 weeks of sailing. To our Esperance list, we need to add a host of routine things like transporting fuel and water to the boat, laundry and re-provisioning. Several items were checked off enroute (the shaft seal leak was something that certainly couldn't wait) while some will be done in Esperance. Some are 5 minute jobs (well, maybe 1-hour jobs – nothing ever takes only 5 minutes to fix on Nine of Cups), while some items like the engine alignment will take a full day. A few of the items like the chartplotter and water tank will have to wait until we are staying put for awhile – probably in Fremantle.

I've made my to-do list for Esperance and started my list for Fremantle. I should have plenty of time to get everything done - assuming Marcie doesn't want to do any frivolous, unimportant things like seeing the local sights or visiting museums. We'll see how that works out.