The Blue View - Broken Rudder Arm...again

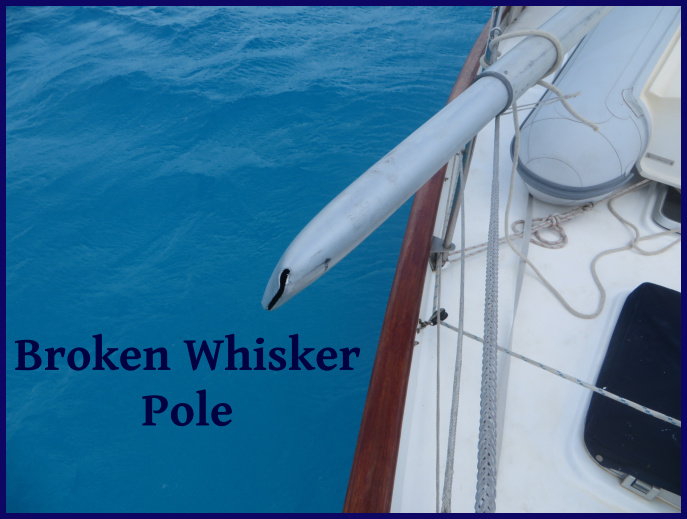

/On a passage from Sarasota, Florida to Colon, Panama in 2009, the rudder arm on Nine of Cups broke. The arm connects the hydraulic steering system to the rudder, and without it we can't steer with either the wheel or the autopilot. The original rudder arm was a massive hunk of bronze, and I was amazed that the rudder built up enough force to break it. This occurred about 25 nm out of Colon, and with the heavy ship traffic into and out of the canal, it wasn't a good place to be without maneuverability. We dug out the emergency tiller and hove-to until I was able to jury rig something to get us into port. A few days later, I found a machinist, and I had him make a another rudder arm for Nine of Cups. The new one was considerably beefier than the old one. It was made from a 1” (25mm) thick steel plate, and was held in place on the rudder stock with two 3/8” (10mm) bolts. I thought this would certainly be up to the job, and it did fine for five years.

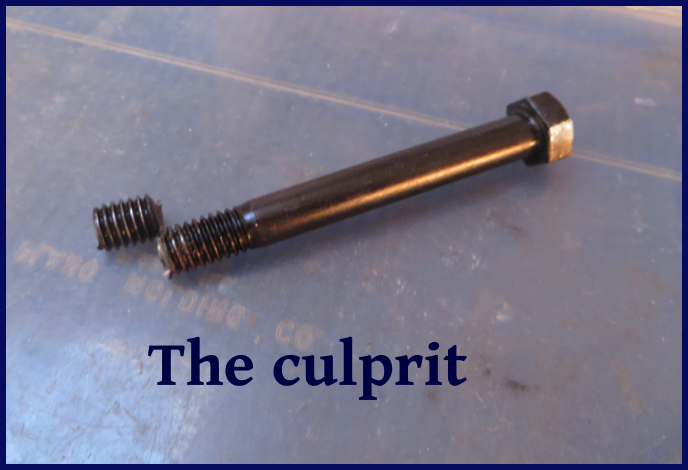

It broke again on the last leg of our Indian Ocean passage from Mauritius to Durban. We had following seas at the time, and apparently the force was sufficient to shear one of the 3/8” bolts in half. I suspect that one of the bolts loosened up, causing a little play between the arm and the rudder. As the waves overtook Cups and hit the rudder, this play would have increased the stress on the bolt.

If it had to happen at all, we were fortunate that it occurred when it did. The weather was reasonably benign at the time and there were no ships bearing down on us. We were also fortunate in that there was enough remaining of the old bolt to grip it with a pair of pliers and back it out. Once again, we retrieved the emergency tiller and hove-to while I worked on it. It took about half an hour to remove the arm, back the broken bolt out, and secure the arm back in place with a new bolt.

Here in Durban, I increased the bolt size to 1/2” (12.7mm) bolts. The yacht club boatyard next door was kind enough to allow me the use of their drill press, and I was able to drill and the tap the holes myself. The new bolts have an extra dose of Locktite along with lock washers to keep them tight. I am optimistic this will do the job.

It's really good I didn't pick civil engineering as my career choice. If the first two iterations of the bridges I designed all fell down while I worked out the problems, it probably would have been a very short career.