The Blue View - Replacing the Cockpit Rope Clutches

/A rope clutch, when engaged, allows a line to be pulled in one direction, but not the other. When the handle on the top of the clutch is lifted, disengaging it, the line tension is released allowing it to be pulled in either direction. It is a handy invention, especially on a sailboat where there are dozens of lines that need to be controlled, adjusted and secured. One of the most common uses of rope clutches is to allow several lines to share one winch. Each line can be adjusted up or down using the winch, then locked in place with its clutch.

Nine of Cups will be 29 in December 2015, and with each passing year, more of her original equipment reaches its “Use By” date. A case in point is the triple rope clutch in the cockpit that is used to control the main halyard, topping lift and spare halyard. It not only looked its age, it would no longer hold the lines in place once they were unwrapped from the starboard winch. Replacing it was on our to-do list for Durban, and a new Garhauer triple clutch was one of the parts Marcie brought back in her luggage from the States.

Unfortunately, the new clutch had a different footprint than the old one, so the job involved more than merely unbolting the old and screwing down the new. A new teak pad to support the clutch would have to be made and finished, and and all but one of the bolts that secure the clutch to the coachroof would need to be repositioned.

As I learned when rebuilding the engine instrument box, teak is difficult to find and very expensive here in South Africa. I did have a small piece aboard left over from another project that would work for the pad, however. I cut it to size, drilled the necessary holes and sanded it down. I finished it using eight coats of a polyurethane finish I like. It is a New Zealand product called Uroxsys (now marketed in many parts of the world as Awlgrip Awlwood MA).

Our coachroof is constructed of a top and bottom layer of fiberglass laminated to a core of balsa. Screwing the clutch directly into the balsa core would be, at best, a short term solution. Even if the balsa had the initial structural strength to secure the clutch under the load of three heavily tensioned lines, which is doubtful, the lateral forces on the screws combined with any moisture that made its way into the screw holes would continually reduce the holding power of the screws. A much better solution would be to bed the bolts in epoxy.

I marked the bolt locations on the coachroof, then drilled oversized holes. The bolts were 1/4” (6mm), so I drilled 1/2” (12mm) holes, double the diameter of the bolts. I also drilled out the old holes that were no longer going to be used with a 5/16” (8mm) bit, only slightly oversized, and then cleaned out all the holes with a vacuum cleaner. I masked both the bottom of the teak pad (I didn't want to accidentally bond the pad to the deck) and the area around the holes. Next, I did a dry fit to make sure everything would go together smoothly later when my hands were all gooey with epoxy, then removed all the parts. The final step of the prep work was to lightly grease each bolt with silicone lubricant to prevent the bolts from bonding with the epoxy.

I keep West System epoxy on hand, and I mixed a small batch (2 full pumps or about 1.6 fl oz) of 105 resin with the equivalent amount of 206 slow hardener. I used a Q-tip to wet out each hole, then mixed 403 filler with the remaining epoxy until it was about the consistency of catsup. Using a small craft stick, I put about 1/2” (12mm) of the thickened epoxy in each new hole, and used all but a small blob of the remaining epoxy to partially fill the old holes.

The next step was to assemble all the parts before the epoxy kicked. I positioned the teak pad and clutch in place, then pressed each screw fully into its hole.

Now the goal was to let the epoxy harden enough to hold the bolts in place, but not to harden beyond the point that it would still bond with additional layers of epoxy. The perfect point is when it is still slightly tacky and can be dented with a fingernail. Since the epoxy in the holes can't be monitored, I kept the mixing pot with the remaining blob of epoxy to check the cure rate. It was fairly hot that day, and it took about 1.5 hours to reach the right hardness. I carefully unscrewed the bolts, then removed the clutch and teak pad and screwed each of the bolts back into their holes. I mixed up another batch of epoxy, again adding 403 filler until it was the right consistency, then filled all the holes. I used a toothpick to probe each hole and release any trapped air bubbles. Then I let the epoxy completely cure for a few days.

I used Sika 291 as a bedding compound, sealant and adhesive between the teak pad and the deck. This raised the teak pad enough that the bolts didn't bottom out in the epoxy when they were tightened down. Alternatively, I could have added a washer under the head of each bolt.

All in all, a lot of work, but I am optimistic it will last another 25-30 years. If so, I'll be in my 90s when it wears out. I just might splurge and hire someone else to do it next time.

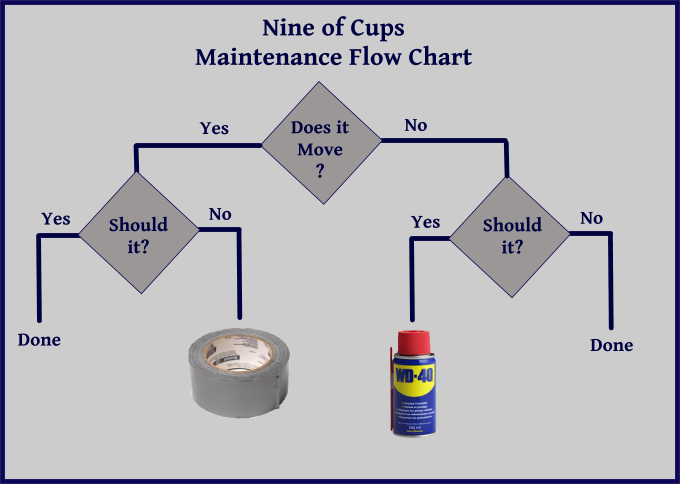

, “You only need two things in life: Duct Tape and WD-40®. If it moves and shouldn’t, use Duct Tape; if it doesn’t move and should, use WD-40®.”

, “You only need two things in life: Duct Tape and WD-40®. If it moves and shouldn’t, use Duct Tape; if it doesn’t move and should, use WD-40®.”