The Blue View - Splicing a Sleeve onto a Line

/In a recent blog, Marcie mentioned visiting the Southern Ropes factory outlet store. What a great place!Not only did they carry every type of yacht rope, but climbing, fishing, water skiing and other specialty ropes as well. I could hardly contain myself as I checked out all the different rope types and discussed the pros and cons of each with the knowledgeable sales person. Marcie, on the other hand, was able to hide her excitement amazingly well.

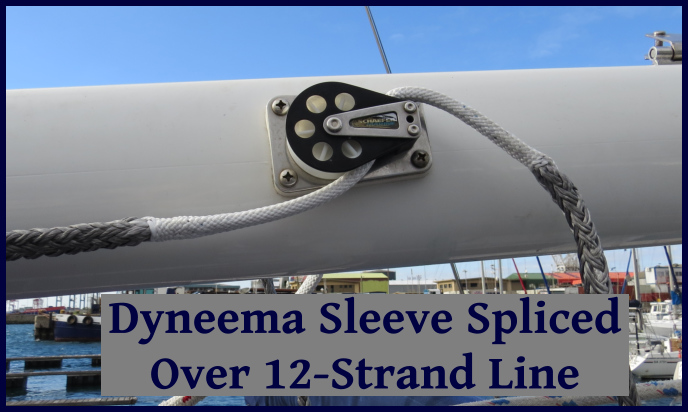

One item I discovered was protective sleeve material. This is a tubular outer cover that can be slid over an existing line and spliced in place to protect the line from chafe. The sleeve is made of UV resistant Dyneema – a material known for its high resistance to chafe. Our reefing lines have a tendency to chafe at one particular spot, and this would be a good remedy. The sleeve material should be purchased in one size larger than the line it is protecting. Since our reefing lines are 10mm, I bought a few meters of 12 mm sleeve material.

In some applications, the sleeve can be merely slid in place and stitched. This would be acceptable for dock and mooring lines. If the line will be passing through blocks and clutches, however, the sleeve should be spliced in place.

There are two types of splices that can be used, depending on the type of line the sleeve will be covering. If the line is a 12-strand type, like Amsteel for example, the splice is quite simple. Once the cover is in place, the combination of the sleeve and the line is essentially a double braid line. I use the method for stripping a cover on double braid class II rope provided by Samson Ropes.

If the line is a double braid type, the splice is more complicated. I cut the cover 12” (30cm) longer than needed. I attach the double braid line to a splicing wand or fid, and slide into the cover.

Next, I mark the cover 6” (15 cm) from one end, and then unravel the strands of the cover from that end back to the mark.

Using a large darning needle, I stitch four sets of strands at a time into the double braid. The splice needs to be tapered, so I vary how far along the double braid each set of strands is stitched. Then I snip off each set of strands where they exit the double braid, and stretch the line until the ends disappear.

(Note the bandaid – I am seldom allowed to use needles or other sharp instruments unattended). Once one end of the cover has been buried in the double braid, I stretch the cover tight and repeat the process with the other end.