The Blue View - Alternative Energy Monitor

/ When we bought our solar panels and wind generators about 15 years ago, we also bought a control panel and monitor to go with it. Although it was quite expensive, it seemed like a good idea at the time. It isolated and combined the inputs from up to three sources, provided a brake and “bump start” for the wind generators, and included a couple of meters to measure the voltages and amps being generated.

When we bought our solar panels and wind generators about 15 years ago, we also bought a control panel and monitor to go with it. Although it was quite expensive, it seemed like a good idea at the time. It isolated and combined the inputs from up to three sources, provided a brake and “bump start” for the wind generators, and included a couple of meters to measure the voltages and amps being generated.

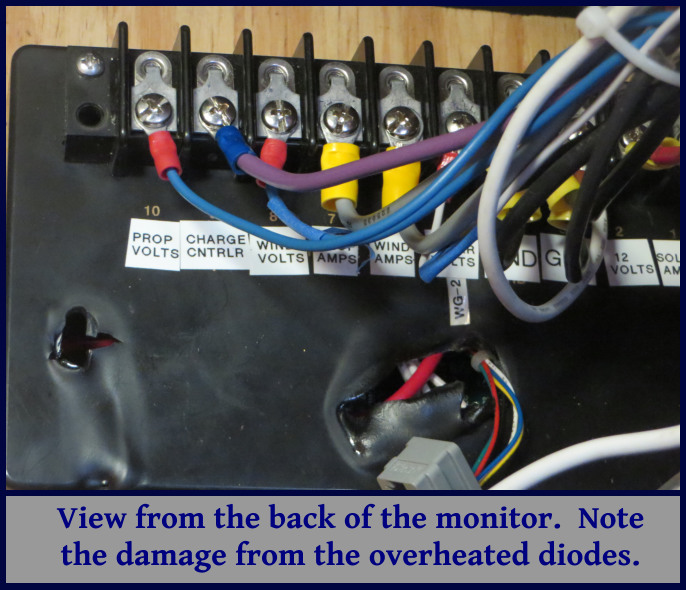

The marketing hype made it sound like it was something we wouldn't want to do without, but it didn't take long to realize we had wasted our money. The brake was ineffective in strong winds, the “bump-start” was never used, and the isolation diodes had a habit of overheating and frying (they actually melted the case on a couple of occasions). The volt and amp meters were only useful in determining whether the various inputs were still working, but when the voltmeter died a few years ago, the monitor lost even this functionality.

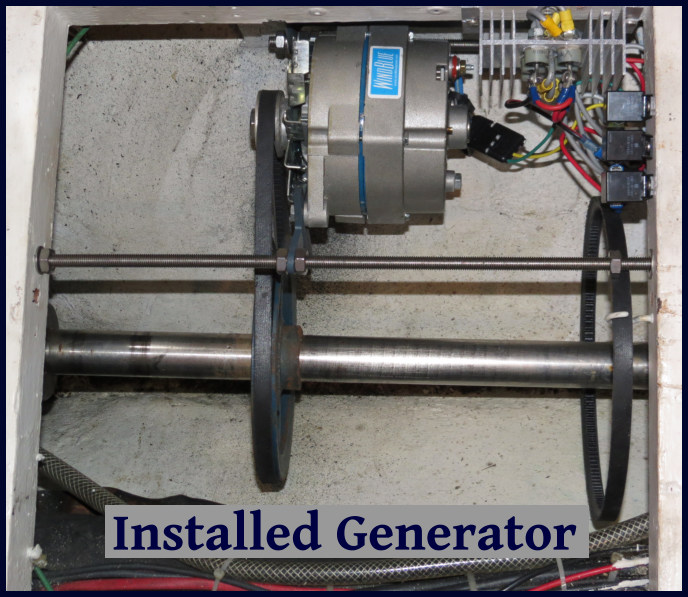

We now have three sources of alternative energy – solar panels, a wind generator/turbine and a generator that is attached to the prop shaft which produces power as we sail. It would be nice to have a simple monitor that would combine these three sources, and display the voltage and number of amps being generated by each source. In addition, it would be nice to keep a running total of the number of amp-hours produced by each input over the previous 24 hours.

I spent most of my working life designing microprocessor-based instrumentation, a career I enjoyed immensely, and it still remains my favorite hobby. We have our own home-brewed refrigerator/freezer controller, a windlass controller and chain counter, pump monitors, and a host of other gizmos ... some of which actually work. When I cut my teeth on microprocessor design several decades ago, it helped to have an advanced degree in electrical engineering and computer science, and required thousands of dollars in developmental tools to develop a microprocessor-based instrument. Now, the development software is often free, and I suspect the basics are taught in elementary schools. On my long list of things I planned to make when I got the chance, a replacement monitor was near the top. When I installed the new prop shaft generator, I decided to build a new alternative energy monitor.

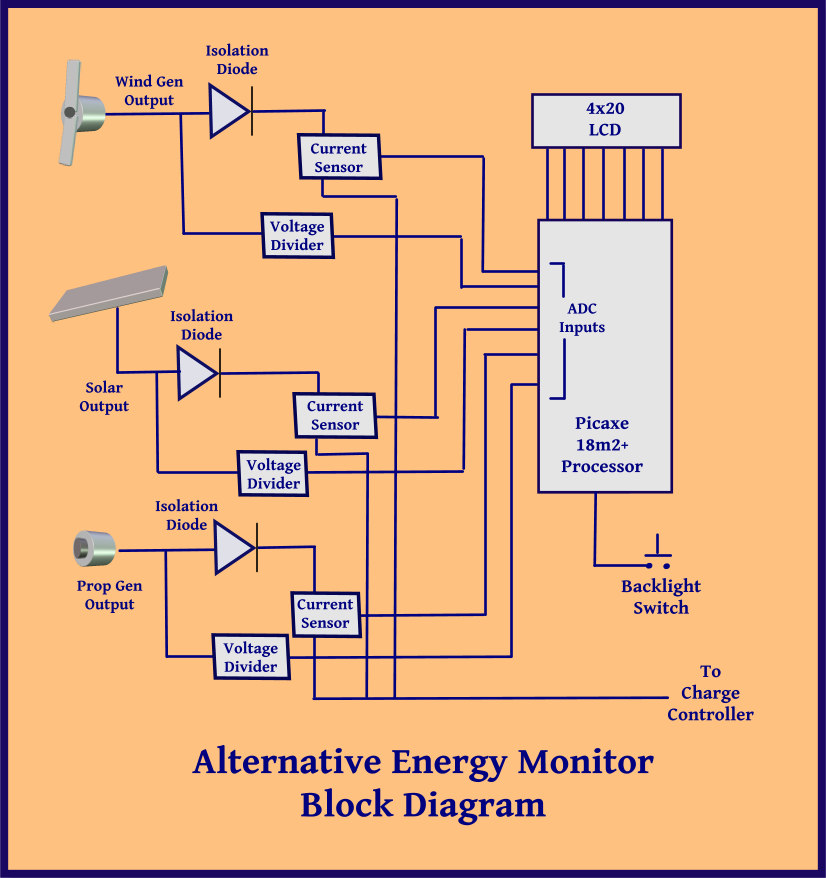

When I was younger, processors were slower and memory was expensive, so it made sense to write software in assembly or C language, so the code would be fast and efficient. The newer processors are loaded with all kinds of hardware features, are orders of magnitude faster and memory is cheap. I have long been fond of Microchip Pic processors, and I especially like the Picaxe versions provided by Revolution Education. They are pre-programmed with download software and a Basic interpreter, making them very easy to use. All the development software is free. What might have taken me weeks or even months two decades ago, can now be done – even by an old guy like me – in days. I used a Picaxe 18m2+ processor as the core of the design.

The block diagram shows the other components. The three inputs are isolated by diodes. (Without the diodes, current can flow in both directions ... when the sun goes down, the solar panels will draw current; when the wind isn't blowing, the wind generator will become a battery-powered motor.) The voltage generated by each input is scaled down using a voltage divider and measured with an A to D converter (ADC). The current is measured with Hall effect transducers – these devices provide a voltage output proportional to the current passed through them. The display is a 4 line, 20 character, backlit LCD. Since the backlight draws a measurable amount of current, it is only turned on when the button is pressed.

As instrumentation goes, this was a pretty simple design, and I am quite happy with the end result. I tackled it in four phases – the electrical design, the software design, the mechanical fabrication and the aesthetics. For those of you who are interested in building your own monitor, I am happy to provide the design details of the project – just send us an email requesting them.

Note from the editor: This is a pretty slick device, but please note that the Captain already had all of these components (backlit display, Hall effect transducers, diodes, Picaxe processors, etc.) aboard. In fact, there's an entire drawer (plus more) dedicated to electronic components alone. So, when I bring a few extra pieces of cloth or a couple shells aboard? Just sayin' …

Note from the Captain: Well yeah – but the electronic components are essential ship stuff and very important. Sea shells???