PEX, Brass Fittings, and the Day It Rained Indoors

/The title isn’t exactly accurate - it actually rained indoors several days in a row. Let me explain…

A few mornings ago, Marcie and I were lying in bed, enjoying our first cup of coffee, and reading the New York Times, when our attic decided it no longer wanted to be an attic and boldly reinvented itself as a municipal water feature. Our pleasant morning ritual was rudely interrupted by the unmistakable drip, drip, drip sound of indoor rain coming from the laundry room. When we opened the laundry room door, we were greeted by a flooded floor, a sagging ceiling, and water pouring out of the light fixture - never a good sign.

We shut off the main water valve and opened a few faucets to drain the lines, then began mopping up the mess. Once it was mostly cleaned up, I cut a hole in the soggy drywall ceiling and stuck my head into the attic to find the source.

We have PEX plumbing in our house, something that is in at least 80% of all newer homes here. PEX (cross-linked polyethylene) is a flexible, durable plastic piping used for hot and cold plumbing. It is cheaper, corrosion-resistant, and easier to install than copper or galvanized steel, and typically lasts 40-50 years. Since our house is on a slab with no basement or crawl space, all the plumbing is run through the attic.

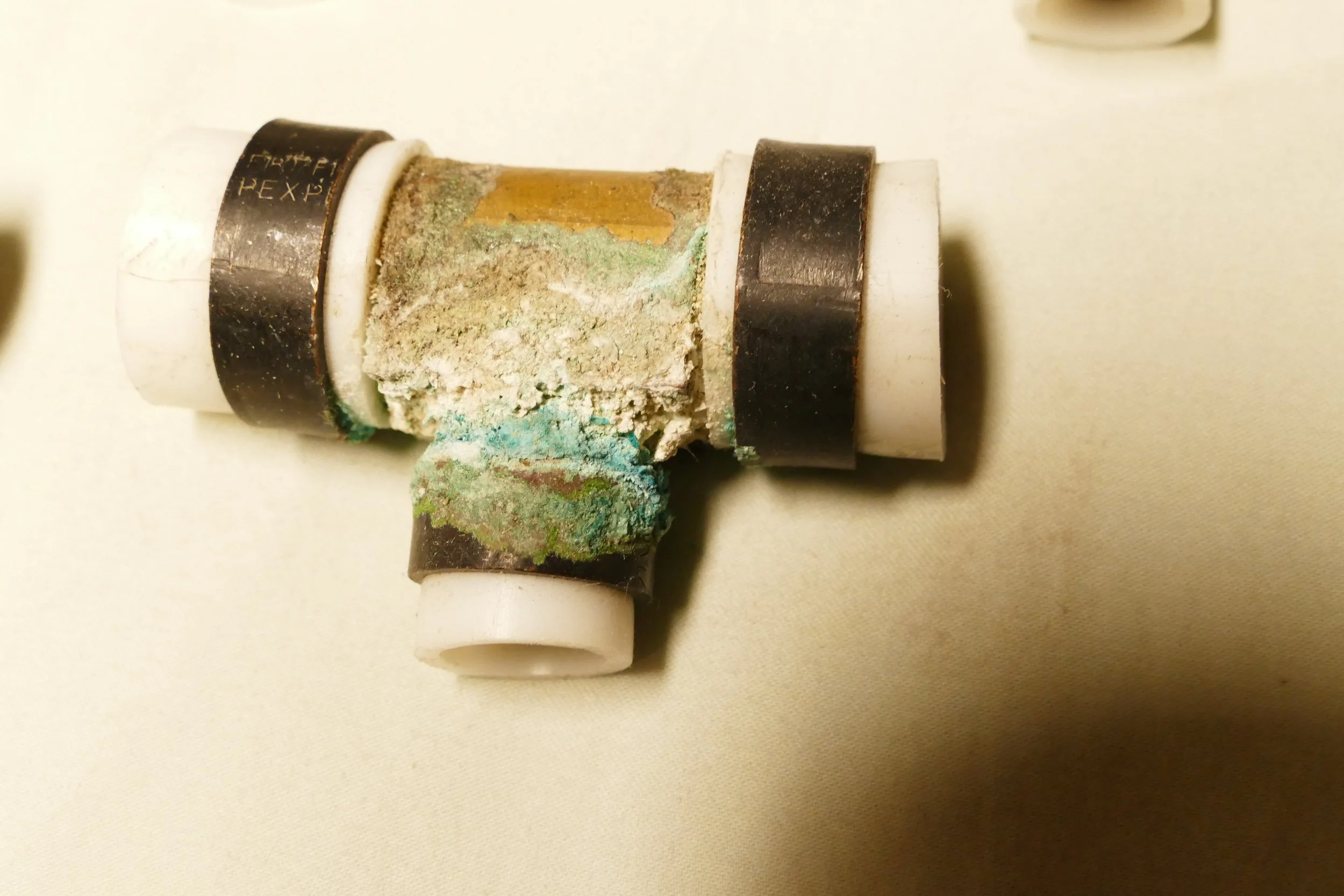

I immediately found the cause of the leak… a corroded brass tee in the cold water line for the washing machine. Brass fittings, which typically last 30-50 years, are used for connecting the sections of PEX pipe together. The fitting is inserted into the pipe, then secured in place and made watertight with either a clamp or a copper ring, both of which are squished down tight using a special crimping tool. Fortunately, I had a manual PEX crimping tool, as well as a few copper rings and a brass tee (from another plumbing project I'd been working on… the subject of a future blog), so I was able to make the repair in short order and turn the water back on. The plan was to let the attic area dry out over a few days, then replace the damaged drywall, texture, and paint. A real pain, but it could have been a lot worse if we'd been gone and hadn't noticed it right away.

The corroded Tee

My assortment of PEX tools

Our house is about 25 years old, so the fitting failed at least five years prematurely. Hopefully, it was just a fluke, but to be safe, I made a note to check other fittings in the next few days to make sure there weren't other corroded fittings.

The next morning, I discovered a small lake in our garage. Sure enough, there was another leak in the attic - followed shortly after by yet another steady drip from the ceiling in one of the bathrooms. This didn't seem like it could be a coincidence that they all started leaking on their own within a day of each other. My theory was that there were at least three corroded brass fittings on the verge of failing, and in the process of repairing the first one, I jiggled the water lines enough to cause the other two to fail. There was also a high likelihood that there were more fittings about to give it up.

I repeated the drill from the original leak - turned the water off, drained the lines, mopped up the mess, then cut more holes in the wet areas of each ceiling to repair the leaks. I spent the afternoon visiting big box stores, rounding up all the fittings and clamps I could possibly need to replace every brass fitting in the attic. I also bought a power crimper to speed the task up, and a moisture meter to assess how much water had gotten into the walls. I planned to start crawling around the attic the next morning.

By the next morning, however, there were two more leaks - both in the master bedroom walk-in closet, soaking the carpeting there. One of them was inside a wall, so I had to add a couple of holes in the wall to complement the ones in the ceiling. No more dawdling - time to get up into the attic.

When I think of an attic, I imagine a spacious room where one might store Christmas decorations and old steamer trunks full of off-season clothes and Grandma's wedding dress. Not so our attic. Ours is not high enough to stand up in, even at the peak. There is the HVAC ducting running to all the rooms, which must be stepped over; a multitude of PEX piping and electrical wiring running everywhere, which shouldn't be stepped on; and only ceiling joists to stand on. One misstep and your foot will go through the drywall ceiling of the room below, and, if you're as clumsy as I am, perhaps land you on the dining room table. It took a while, and it wasn't my favorite DIY job, but I did trace every PEX line and replace all the fittings - 17 in all, and of these, seven were badly corroded.

The corroded parts

Replacing the fittings is just the beginning of the story; the next part of the saga is drying out or removing all that wet drywall before mold could set in, then repairing it all - a sad tale for another blog.

A few asides before I wrap this up…

I wondered why our fittings corroded faster than their expected lifetimes. We have very hard water here in Las Vegas, with high concentrations of calcium and magnesium. These minerals in particular, leach the zinc from the brass, leaving it weak and porous. One sign of dezincification is green or white deposits, which was evident on the leaking fittings.

Last year, we installed a NuvoH2O water treatment system that is designed to prevent corrosion on metal components, including brass fittings. Hopefully, the new fittings will last longer than the 25 years the original fittings lasted. In any event, it's doubtful either of us will be around by then to know whether the system worked.

We discovered, after talking to some of our neighbors who are the original owners of their homes, that there was a class action suit against Pulte homes in 2010 for their use of substandard brass plumbing fittings in our area. Perhaps this was why our fittings lasted only 25 years. We have no idea whether the owner of our house at the time received a settlement and did nothing to replace the fittings, or was even aware of it.

I also wondered why the cold water fittings were the only ones to leak. Only one hot water fitting showed any signs of corrosion. According to Google AI, one reason may be that heating the water removes much of the oxygen in the water, and the oxygen in the cold water may be combining with the dissolved metals to form an "oxide" which speeds up the corrosion. Or perhaps more cold water is used than hot, and the increased flow causes the cold water fittings to corrode faster.

Interesting why, with one exception, only the cold water fittings corroded

Finally, PEX fittings are also available in plastic, which are cheaper and much more corrosion-resistant than brass. Why not replace all the fittings with plastic? I chose to stick with brass fittings because good quality brass is stronger and has a longer lifetime than plastic fittings - assuming the NuvoH2O system does what it’s advertised to do. Again, it's highly unlikely either of us will be around in 25 years to prove or disprove that assumption.

See you next time…