There are two criteria I’ve included, which will be helpful when comparing the batteries for our application. One is the recharge time from 50% DOD to 80% of full charge and from 50% DOD to full charge. The time we spend running the engine every day to recharge the batteries is an important consideration. I’ve also included an estimate of the time spent each month on maintenance. Given how I routinely mistreat them, even the ‘maintenance free’ batteries require some attention each month, whether it is something as simple as giving them a full charge or performing a full equalization on a routine basis.

There are two criteria I’ve included, which will be helpful when comparing the batteries for our application. One is the recharge time from 50% DOD to 80% of full charge and from 50% DOD to full charge. The time we spend running the engine every day to recharge the batteries is an important consideration. I’ve also included an estimate of the time spent each month on maintenance. Given how I routinely mistreat them, even the ‘maintenance free’ batteries require some attention each month, whether it is something as simple as giving them a full charge or performing a full equalization on a routine basis.

Flooded Lead Acid Batteries. These are similar to the batteries that have been used in cars for the last 100 years, but these are designed for deep discharging. The biggest advantage they hold is their inexpensive price – comparatively speaking. These are vented batteries - as they are charged, the water boils off, so the water level should be checked frequently, as should the specific gravity. They are also subject to sulfation and stratification, thus as they age, they should be equalized every month or two. The charging rate is low – the Rolls batteries set the maximum bulk charge rate at 15% of the total 6 hour amp-hour rating, so for an 800 ah battery bank, the maximum bulk charge would be 90 amps. Using their formulae, it would take a total of 7.2 hours to fully recharge a battery bank that was at 50% DOD. On the other hand, they are fully warranted for 2 years and have a seven-year pro-rated warranty.

Pros

- Inexpensive

- Good life expectancy if properly maintained

Cons

- A lot of maintenance

- Will spill acid if knocked over (or the boat is knocked down or capsized)

- High rate of self-discharge

- Low charge rate

- Batteries will release hydrogen gas while charging, so battery compartments must be vented.

- Heavier than other technologies

Manufacturers: Trojan, Exide, Surrette, U.S. Battery

Weight: 110-115lb (50-52kg) per 200 ah

Recharge Cycles: 1000-1500, if properly maintained

Recharge time: 50% to 80% in 2.7 hours; 50% to Full Charge in 5.7 hours

Monthly maintenance time estimate: 12-14 hours, including a monthly equalization

Expected Life: 5-7 years

Cost of Batteries: About $1.30/ah - Four batteries totaling 820 ah: $1080

Gel. Gel Cell batteries suspend the electrolyte in a paste-like gel, which allows electrons to flow but will not leak if the battery is tipped over or the case is broken. They are leakproof and even submersible. They have a high number of recharge cycles and are maintenance free – in fact, they cannot usually be equalized. The recharging cycle must be very carefully regulated and requires a smart charger. The cost is fairly high.

Pros

- No maintenance

- Leakproof

- High number of recharge cycles

Cons

- Relatively high cost

- Charging must be carefully controlled

- Heavy

Manufacturers: Trojan, Deka (Deka/MK produce privately labeled batteries for several other companies)

Weight: 155-165 lb (70-75 kg) per 200 ah

Recharge Cycles: 600-1000 if properly recharged

Recharge time: 50% to 80% in 1.1 hours; 50% to Full Charge in 3.6 hours

Monthly maintenance time estimate: 4 hours – at least one full charge a month

Expected Life: 5-6 years

Cost of Batteries: About $3.50/ah – Four batteries totaling 900 ah: $3180

AGM. Absorbent Glass Mat (AGM) batteries consist of negative and positive plates sandwiched between layers of glass mat. There is no liquid acid to spill and the battery is sealed with pressure relief valves that prevent venting of hydrogen gas under normal circumstances. There are several different versions of AGM batteries, but four products are of particular interest: Lifeline, TPPL, Spiral Wound and Carbon Foam. I’ll talk about each below:

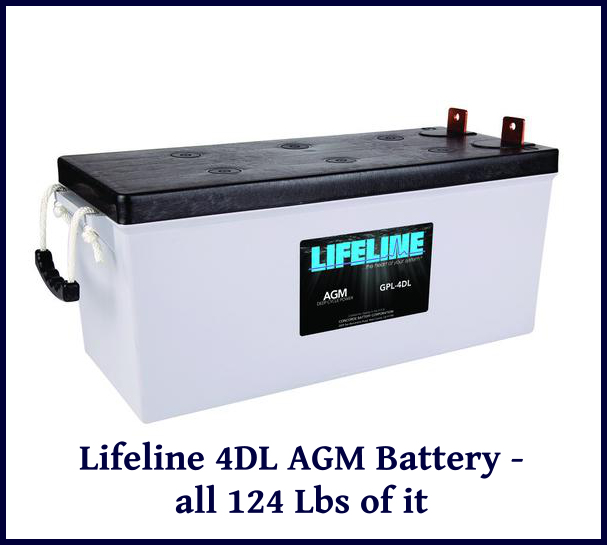

Lifeline AGM. The Lifeline AGMs we’ve had for almost eight years now have obviously served us well. They are quality made and designed for deep cycle applications.

Pros

- Maintenance free

- Very fast max recharge rates (up to 5c)

- Moderate price

- Good life if properly maintained

- Long shelf life – slow self-discharge rate

- Can be equalized

Cons

- Heavy

- Must have a charge rate of at least .2c to obtain max number of cycles (min of 160 amps for an 800ah bank);

- Requires periodic equalization if not routinely returned to full charge regularly

Recharge Cycles: 1000

Recharge time (max charge rate): 50% to 80% in 8 minutes; 50% to Full Charge in 2.5hrs

Recharge time (200 amp alternator and 800ah bank): 50% to 80% in 1.2 hours; 50% to Full Charge in 5.7 hours

Monthly maintenance time estimate: 10-12 hours – at least one full charge/month plus an equalization quarterly

Expected Life: 6-8 years

Cost of Batteries: $3.11/ah – Four batteries totaling 820ah: $2650

TPPL. The plates in the Thin Plate Pure Lead (TPPL) AGM batteries are, as the name suggests, constructed of 99.99% pure lead rather than a lead alloy. The manufacturer claims this allows them to utilize thinner plates and to insert more of them in the same space, effectively increasing plate area.

Pros

- High number of cycles, and a very high recharge rate, up to 3.1c

- Like most AGMs, they also have a slow self-discharge rate

- Maintenance free and non-spillable

Cons

- Must have a high recharge rate (.4c) to optimize cycle life

Manufacturers: Odyssey, Northstar

Recharge Cycles: 700-800

Recharge time (max charge rate): 50% to 80% in 6 minutes; 50% to full charge in 10 minutes

Recharge time (200 amp alternator and 800ah bank): 50% to 80% in 1.05 hours; 50% to Full Charge in 4.0 hours

Monthly maintenance time estimate: 6 hours – one full charge per month

Expected Life: 4-5 years

Cost of Batteries: $2.90/ah – Eight batteries totaling 800ah: $2300

Spiral Wound. These batteries also use plates constructed of 99.99% pure lead, but the thin lead plates are made of a continuously cast strip wound in a spiral. A glass mat is wound alongside the plate, forming sort of a jelly roll. The glass mat serves to insulate the plates and to provide a means of suspending the electrolyte. The manufacturers of these batteries don’t seem to want to provide a lot in the way of comparative specs, like recharge cycles, equalizing, etc. so I have provided estimates below.

Pros

- High initial charge rate

- Slow self-discharge rate

- Sealed and non-spillable

Cons

- Must charge a long time to reach full charge;

- No equalization,

- Recharge cycles will be less without routine full charges

Manufacturers: Optima, Yuasa, Exide

Recharge Cycles: 300-400

Recharge time (max charge rate): 50% to 80 in 1.05 hours; 50% to full charge in 6-8 hours

Recharge time (200 amp alternator and 800ah bank): 50% to 80% in 1.05 hours; 50% to Full Charge in 6-8 hours

Monthly maintenance time estimate: 8 hours – one full charge per month

Expected Life: 4 years

Cost of Batteries: $2.97/ah – Ten batteries totaling 775ah: $2230

Carbon Foam. A few years ago, Caterpillar developed a new battery technology that was intended for their heavy equipment. They embedded a carbon foam grid onto the internal negative plates of an AGM battery. This grid prevents large sulfate crystals from forming, making it more suitable for deep discharge cycling. They spun the division off, and after a few false starts, the OceanPlanet Energy/Bruce Schwab company obtained the rights and now builds and markets the technology as the Firefly Oasis battery. Practical Sailor and Nigel Calder both put it through its paces with good results. It hasn’t been out long enough to do any long-term testing, but the short-term testing was quite positive. It has a large number of charge cycles and can be partially recharged indefinitely without affecting its long-term performance – an important feature.

Pros

- High number of cycles, and a high recharge rate, up to 2.5c

- Like most AGMs, they also have a slow self-discharge rate

- Maintenance free and non-spillable

- Can be routinely operated at between 50% charge and 80% charge without affecting performance

Cons

- More costly than other AGMs

Recharge Cycles: 3600 at 50% DOD

Recharge time (max charge rate): 50% to 80% in 1 hour; 50% to full charge in 3 hrs (estimate)

Recharge time (200 amp alternator and 800ah bank): 50% to 80% in 1.25 hours; 50% to Full Charge in 3.5 hours (estimate)

Monthly maintenance time estimate: 2 hours – one restoration charge per quarter

Expected Life: 10 years

Cost of Batteries: $4.86/ah –Seven batteries totaling 812ah: $3400

Lithium-ion. There are several lithium-ion based batteries, and some, like the Samsung Galaxy Note 7 have garnered a lot of negative publicity. The type of lithium-ion battery used in cell phones is Lithium-Cobalt-Oxide, which has a very high energy density. If it is charged at too high a rate or if the outputs ever short, however, the battery will overheat, possibly resulting in a fire or even an explosion. The type used in our application is a Lithium-Iron-Phosphate battery, which has a lower energy density, but is also much more stable and economical. Even though it is more stable, however, a battery monitoring system must be provided which will prevent the cells from overheating, overcharging, discharging too quickly, or becoming totally discharged.

Pros

- Lightweight

- Fast charge rate

- Large number of recharge cycles

- Large usable capacity – 80% of capacity vs. 50% of lead acid

- Can be routinely operated at between 50% charge and 80% charge without affecting performance.���

Cons

- Expensive

- Requires battery monitoring system

Recharge Cycles: 3000-5000

Recharge time (max charge rate): 50% to 80% in 1 hour; 50% to full charge in 2 hrs

Recharge time (200 amp alternator and 800ah bank): 50% to 80% in 1 hours; 50% to Full Charge in 2 hours

Monthly maintenance time estimate: 2 hours – one full charge per month

Expected Life: 10 years

Cost of Batteries: $11.54/ah – Three batteries totaling 780ah: $9000

So, after all that, what’s the best battery for our application? Stay tuned until tomorrow for the exciting conclusion.

So, after all that, what’s the best battery for our application? Let’s start by comparing the true cost of each battery type over its life.

So, after all that, what’s the best battery for our application? Let’s start by comparing the true cost of each battery type over its life.

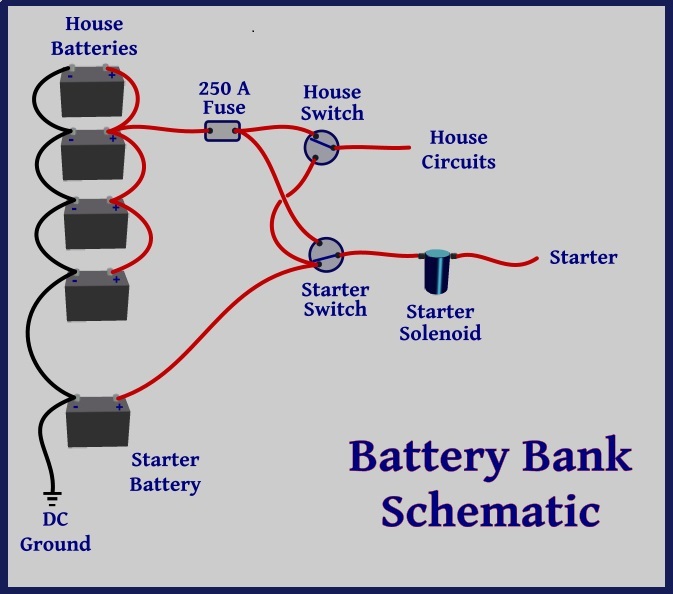

Boat batteries come in two basic types – starter batteries and house batteries. Starter batteries are designed to provide very large, short term current as the engine is started, then are recharged while the engine is running. These batteries are usually rated by their Cold Cranking Amps (CCA) - a measure of how many amps of current the battery can put out over a 30 second period without discharging the battery. For example, a battery with a CCA rating of 500 amps can provide 500 amps of current over a 30 second period in freezing temperatures and still maintain a voltage of at least 7.2 volts.

Boat batteries come in two basic types – starter batteries and house batteries. Starter batteries are designed to provide very large, short term current as the engine is started, then are recharged while the engine is running. These batteries are usually rated by their Cold Cranking Amps (CCA) - a measure of how many amps of current the battery can put out over a 30 second period without discharging the battery. For example, a battery with a CCA rating of 500 amps can provide 500 amps of current over a 30 second period in freezing temperatures and still maintain a voltage of at least 7.2 volts.