The Blue View - Chainplate Update

/We are finally making some progress on the chainplates, although it has been one step backwards for each two slow steps forward. The most recent setback was when I discovered, after the stainless for the chainplates was all cut, drilled and polished, that the metal for the backstays was the wrong thickness – 3/8” (10mm) instead of 1/2” (12mm). We will lose another week while they are redone.

There are two bends that need to be made in each chainplate, but determining the location of each bend has to wait until the part is attached to the hull. Once attached, the precise location and angle of the first bend can be measured and marked, then the chainplate must be removed and taken back to the machinist to be bent. Next the parts will be reattached to the hull, the second bend measured and marked, and again sent to the shop to be bent. All this has to wait until the holes have been drilled in the hull.

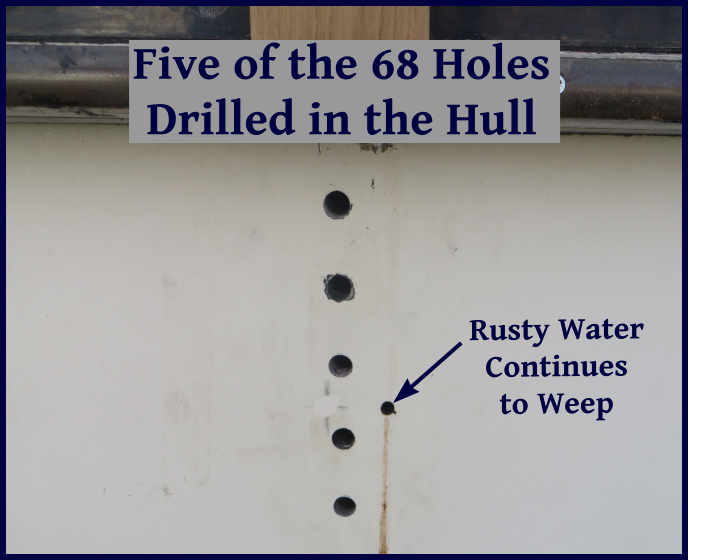

Most of the holes in the hull have now been drilled, which was a major undertaking. A total of 68 holes needed to be drilled, most of which pass not only through the hull, but the old stainless chainplates as well. All but eight of these have been drilled, and these remaining holes will wait until the first bend is made and the chainplates reattached. One thing we noticed as the holes were drilled was that rust colored water continues to seep out from the old chainplates – continued confirmation that we are doing the right thing here and didn't wait any longer.

The exterior carpentry is done. The last phase was fabricating and attaching the teak spacers to the hull, and this has now been completed.

The interior cutouts have all been made, luckily, except for one in the forward berth, they are all inside bookshelves or lockers. I used my Ryobi version of the Fein tool to make the cuts. I will make teak pieces to cover the holes – a few in the next few days with the teak I have on hand and some later when I can get less expensive teak elsewhere. I want to be able to easily remove the hole covers later so that the new chainplates and bolts can be inspected periodically.

Progress is being made, although painfully slow. Maybe another week until the project is complete – assuming no more major setbacks. Using Marcie's project formula, it'll be another two weeks.