The Blue View - Finished at Last

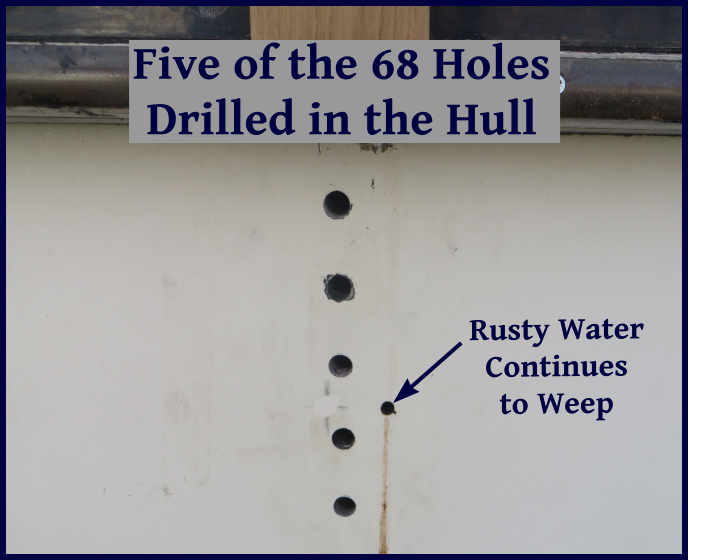

/We were getting quite used to being able to check out our surroundings with a glance through any of the 68 new holes in the hull, and were beginning to appreciate the added ventilation they provided, but alas, all good things must come to an end,. The chainplates are now firmly bolted in place and each hole has its own 1/2” bolt, nut, washer and enough Sika to keep the ocean on the outside. The chainplate project is now complete.

The last few days have been busy. Each chainplate required two bends, one to conform to the hull shape and one to match the angle of the shrouds. This necessitated that each chainplate be bolted on so that the first angle could be measured, then removed and taken to the machinist to make the first bend. Then the process was repeated with all eight chainplates for the second bend. All in all, a time consuming process.

The next step was to bolt them back in place and shape the teak pads that act as spacers between the chainplates and the bulwarks. This took me the better part of two days – a lot of sanding was required.

Then the chainplates were removed once more. Every time they were handled new scratches appeared on the surface of the stainless, and the bending process introduced tool and stress marks, so they were sent out for a final polishing.

There was another slight complication with the bolts. They had to be ordered in, and the choice was either too short or too long. Not a tough decision, but it meant all the bolts had to be cut off and dressed. Since the hull thickness varied from about 1” to more than 2”, the length of each bolt varied as well. It took another half day to figure out how long each bolt needed to be and cut them to length.

The last step was to apply Sika bedding compound around the holes, put the chainplates in place and bolt each one down. The objective was to make sure the chainplates were stronger than the wire shrouds and stays they were holding, and I am quite convinced this goal was met. And it looks about as good as having eight steel straps bolted to the outside of the hull can look.

The interior finish work will have to wait until another port, but other than that, the interior of Nine of Cups is back together and everything is stowed. Tomorrow, we start replacing the rigging. More to come...