The Blue View - Chainplate Update

/We are making some progress on the new chainplates. Now that the metal has been cut, the machinist came down to look at Nine of Cups and take some measurements. Sort of like “Ready, Fire, Aim...” in my mind. There was some initial angst when we thought the chainplates had been cut too short, but after talking it through with the shipwright and with Dave, we all agreed the newly cut metal would work.

The marine architect made an appearance as well. He did the original design based on photos, assuring us that he knew the boat quite well and that a trip to the yacht club to actually look at Cups was unnecessary. This was borne out, as you may remember, when his first iteration of the design was totally incorrect, having the chainplates bolted to the bulwark and into the core of the deck. We had a discussion, now moot since the metal was already cut, about how the chainplates might have been designed to look less industrial and more aesthetically pleasing. He gave us several less than compelling reasons why this wasn't done, such as “it would have added extra weight to the boat” (two pounds in extra metal would make a difference on our 21 ton boat?), “designs that bolted the chainplates into the bulwark wouldn't be as strong” (not something I was suggesting, and anyway, wasn't that exactly the way he first designed it???), blah, blah, blah … We weren't really impressed.

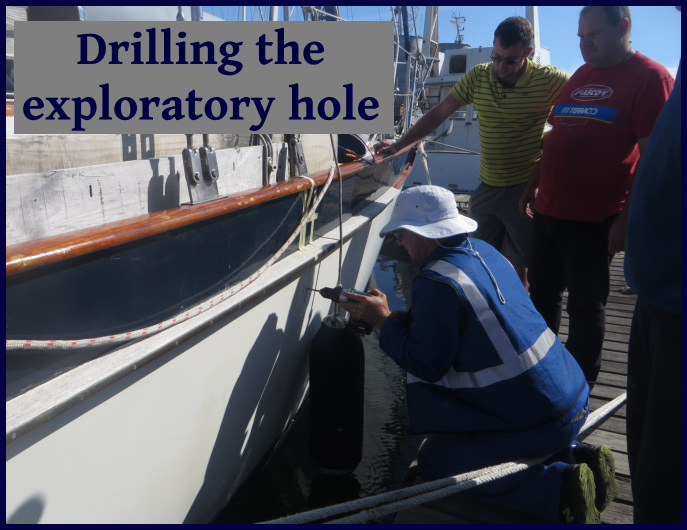

The shipwright came shortly after, and following much measuring and discussion, he drilled a small exploratory hole through the hull to determine how thick it was and where the bolts would protrude into the interior. When the bit came into contact with the old chainplate, water started running out of the hole – maybe a teaspoon or two. If water had made it that far into the hull, approximately two feet down from the cap rail, it was almost certain that the old chainplates would be suffering from crevice corrosion – more confirmation that we were doing the right thing. Another small hole was drilled alongside the chainplate, and no water came out, some assurance, at least, that the water ingress was confined to the column alongside the chainplate.

We are now waiting for the machinist to drill the holes in the chainplates and polish the stainless steel to a mirror finish, after which the hull drilling and cutting will begin in earnest. I sound quite negative, but in actuality, I am still optimistic that the project will turn out fine.

Stay tuned...